|

Semiconductor Room What are semiconductors? Semiconductor manufacture |

A Critical Dimension SEM (CD-SEM: Critical Dimension Scanning Electron Microscope) is a dedicated system for measuring the dimensions of the fine patterns formed on a semiconductor wafer, and it is mainly used in the manufacturing lines of electronic devices of semiconductors.

Three main features that differ from the general-purpose SEM:

1. The primary electron beam irradiating to the sample has low energy of 1keV or below.

Lowering the energy of the electron beam can reduce the damage to the sample due to charge-up or electron beam irradiation.

2. Measurement accuracy and repeatability is guaranteed by improving magnification calibration to the maximum extend.

Measurement repeatability is around 1% 3σ of the measurement width.

Measuring a fine pattern on a wafer.

A sample wafer is put inside a wafer cassette (or a pod), which is placed on the system. The condition and procedures of the dimensional measurement are input into a recipe* in advance. When the measurement process is started, the system will automatically take the sample wafer out of the cassette, load it into the system and measure the desired positions on the sample. When the measurement is finished, the wafer will be returned to the cassette.

Measurement system uses the grey level (contrast) signal of the SEM image.

Measuring a fine pattern on a wafer.

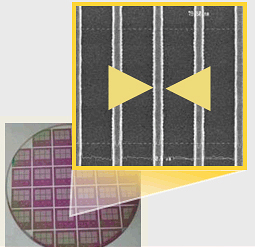

An example of SEM image obtained by CD-SEM is shown below. Fig.4-1 shows a line profile drawn on top of an SEM image of a photoresist line. The relationship between the cross-sectional view of the photoresist line and the SEM image is shown in Fig.4-2. Furthermore, the relationship between the line cross-section and its line profile is shown in Fig.4-3.

That is, the image in Fig.4-1 gives the line profile, which in turn gives the line width. If the line cross-section is in the shape of a trapezoid as in Fig.4-3, the width at the top and bottom will be different. In that case, the measurement position will be specified in the recipe. In addition, the desired height position can also be specified.

Fig.4-2. Relationship between the SEM image of line & space and the schematic cross-sectional view |

Fig.4-3. Relationship between the line schematic cross-sectional view and the line profile |

Critical dimension measurement is mainly performed in the following operations of the wafer fabrication process.

Critical dimension measurement of photoresist pattern after development

Measurement of the contact hole diameter / via-hole diameter and the wiring width after etching

Hitachi Advanced High Resolution CD-SEM

Since Hitachi launched its first CD-SEM in 1984, it has been consistently following the critical dimension measurements method based on the SEM image, evolving and maintaining excellent measurement repeatability for over 30 years. While maintaining high resolution that is compatible with the semiconductor microfabrication trend, Hitachi is providing robust system demonstrating a high availability and incorporating various new functions required by the manufacturing and development lines meeting customer's needs.

Hitachi Advanced High Resolution CD-SEM CG5000

|