Ion Beam Milling System Leica EM TIC 3X

|

||

|

Achieving high quality cross-sections of almost any material, revealing the internal structures of the sample with scarcely any deformation or damage was never before more convenient than now, using the Leica EM TIC 3X.

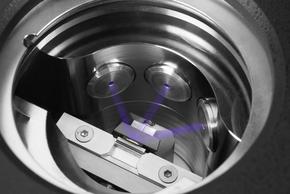

The Triple Ion Beam Milling System, Leica EM TIC 3X allows production of cross sections of hard/soft, porous, heat sensitive, brittle and heterogeneous material for Scanning Electron Microscopy (SEM), Microstructure Analysis (EDS, WDS, Auger, EBSD) and, AFM investigations.

Three individually controlled ion beams , rotary stage, cooling stage and multiple sample stage ensure milling at high rates, cutting broad and deep into the sample resulting in high quality cross-sections.

Connectivity with the Leica transfer system provides for perfect cryogenic surfacing of biological, geological or industrial samples subsequently transferred under cryo and vacuum conditions to coaters and (cryo) SEM.

Liên hệ với chúng tôi Liên hệ với chúng tôi

|

|

|

Your Advantages

Vacuum Transfer Docking PortThe VCT docking port in combination with the Leica EM TIC3X offers the perfect workflow for surfacing environmentally sensitive samples which can be subsequently transferred to coating and/or SEM systems under inert gas/vacuum conditions More information Take a look at the latest publication

(SEM cross sections were obtained using the Leica EM TIC3X/VCT) |

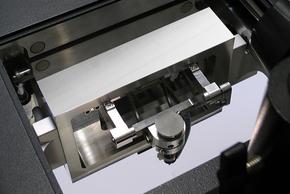

Sample HoldersA choice of various sample holders for almost every sample size ensures best possible flexibility for users. Take a look at the sample holders |

Top-rate PerformanceUnique Triple Ion Beam System optimizes the cross-section quality and reduces working time with its ability to cut broad and deep at high speeds. Up to three samples can be processed in one session. This makes the Leica EM TIC 3X a perfect instrument for high through-put laboratories |

Configurable SystemDepending on your preparation needs the Leica EM TIC 3X can be configured individually by using interchangeable stages - Standard stage, Multiple sample stage, Rotary stage, Cooling stage or VCT Docking Station. Take a look at the stages |

Clear Visualization of the Surface TopographyIn addition to cross sectioning, the same holder can be used for cleaning and contrast enhancement.

|

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.