● Advanced Real-Time SCADA and PID Control.

● Open Control + Multicontrol + Real-Time Control.

● Specialized EDIBON Control Software based on Labview.

● National Instruments Data Acquisition board (250 KS/s , kilo samples per second).

● Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

● Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

● Capable of doing applied research, real industrial simulation, training courses, etc.

● Remote operation and control by the user and remote control for EDIBON technical support, are always included.

● Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic & Software).

● Designed and manufactured under several quality standards.

● Optional CAL software helps the user perform calculations and comprehend the results.

● This unit has been designed for future expansion and integration.

A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

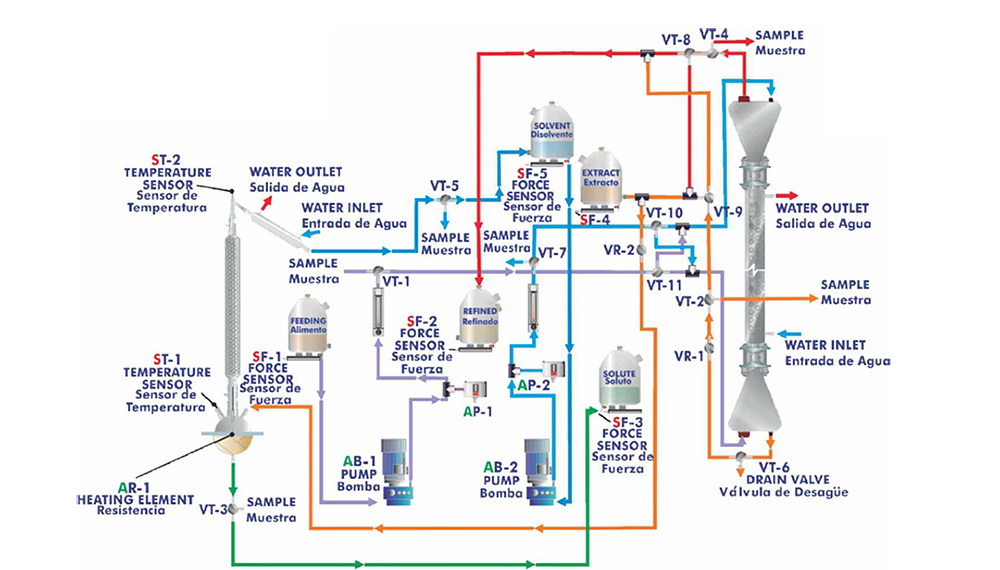

The Computer Controlled Liquid-Liquid Extraction Unit (UELLC) is a laboratory scale unit designed to study the separation of the components of liquid mixtures by contact of the mixture with an immiscible solvent in which these components are preferentially soluble.

The extraction process is carried out in the glass liquid/liquid extraction column, which is composed of a jacketed glass packed column with two enlarged end sections. The joints between the three sections of the column are sealed with PTFE gaskets. The column is filled with glass Raschig rings that are supported on a perforated PVC plate. Feed for the column is stored in the feeding tank from where it is pumped by a computer controlled diaphragm pump. It passes through a flowmeter and enters the base section of the column via an injector mounted on it. Refine (phase with low content of solute) leaves the top of the column through a pipe and is collected in a refined tank.

The solvent supply tank provides the feed for a computer controlled diaphragm pump. The solvent is pumped and passes through a flowmeter, then enters the top of the column via an injector. Extract (phase with high content of solute) leaves the bottom of the column through a pipe and is collected in an extract tank. A drain valve is fitted in the extract line.

The supply circuits and product collection circuits include two pressure switches that switch off the pumps when the pressure is high, two sampling taps to collect samples, three-way directional valves to direct the different currents and a regulation valve to control the height of the interface. The distillation process is carried out in the distillation column boiler. The distillation column is made up of a glass section and contains Raschig rings made of glass. It is mounted closed to the extraction column and fitted at such a height that the solute may be drained into the solute tank. Heating is done by means of a heating mantle (with control of the temperature in the column head) in the base of the boiler andthe boiler temperature is indicated on a temperature sensor. The boiler lid is perforated where the distillation column is fitted and a pipeline allows to drain the extract from the extract tank. The boiler-solute tank circuit includes a sampling tap to collect samples.

The dissolvent vapor phase is condensed in the coolant column and re-cycled to the solvent tank to recovery the dissolvent and to provide a closed

circuit. Then, the solvent can be re-cycled continuously. All storage tanks have force sensors to measure the mass in the five tanks (feed, refined, solvent, extract and solute) and to calculate the liquid

volume.This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control

Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

|

1.- Preparation of acid–base titration of the feed. Additional practical possibilities: |

Other possibilities to be done with this Unit: |

|

- Electrical supply: single-phase, with ground, 220V./50Hz or 110V./60Hz. |

| Unit: |

- Dimensions: 1400 approx. x 700 x 1950 mm.(55.11 x 27.55 x 76.77 inches approx.) |

| Control Interface Box: |

- Dimensions: 490 x 330 x 310 mm. approx. (19.29 x 12.99 x 12.20 inches approx.). |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.