● Advanced Real-Time SCADA and PID Control.

● Open Control + Multicontrol + Real-Time Control.

● Specialized EDIBON Control Software based on Labview.

● National Instruments Data Acquisition board (250 KS/s , kilo samples per second).

● Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

● Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

● Capable of doing applied research, real industrial simulation, training courses, etc.

● Remote operation and control by the user and remote control for EDIBON technical support, are always included.

● Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic & Software).

● Designed and manufactured under several quality standards.

● Optional CAL software helps the user perform calculations and comprehend the results.

● This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

EDIBON's distillation unit, in its different versions, is one of the most powerful laboratory tools for the study of the variables that affect the distillation process.

The student can investigate the principles that rule the mass and energy transference, as well as determine optima operation point to carry out a big quantity of separations.

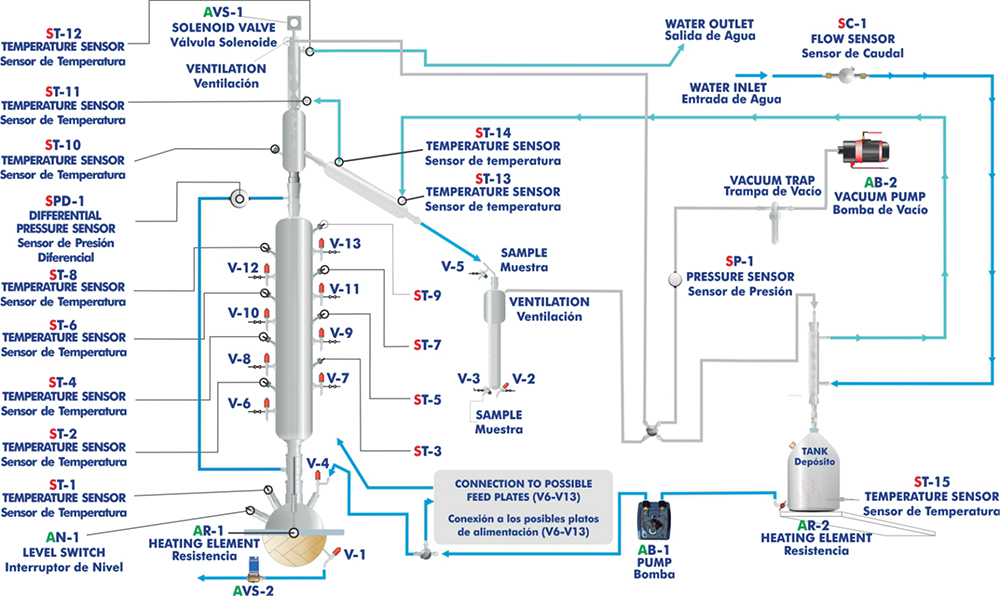

This unit is basically composed by a boiler on which two types of columns can be adapted (plate columns and Raschig rings column), a reflux system, a tank for distillation, a vacuum pump and a feeding pump (for continuous feeding). The steam that goes to the head of the column is sent to a total condenser. The cooling water flow that crosses the condenser is

regulated and indicated in a flow sensor. Distillation can be carried out at low pressures with the help of an adjustable vacuum pump.The pressure loss in the column can be measured with a pressure sensor. It allows continuous operation and batch operation.

For proceeding to continuous feeding, a pump that can inject the substance directly into the boiler or in any of the plates is available.

The temperatures of the system are measured by sensors placed in strategic positions.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a

Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software

Packages, for controlling the process and all parameters involved in the process.

|

1.- Preparation of solutions. |

Additional practical possibilities: |

|

- Electrical supply: 220 V./50Hz. or 110V./60Hz. |

| Unit |

- Dimensions: 900 x 600 x 2600 approx. mm. (35.43 x 23.62 x 102.36 inches approx.) - Weight: 200 Kg. approx. (441 pounds approx.) |

| Control Interface Box |

- Dimensions:490 x 450 x 470 mm. approx. (19.29 x 17.71 x 18.50 inches approx.). - Weight: 20 Kg. approx. (44 pounds approx.). |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.