|

Some Practical Possibilities of the Unit: |

12.- Mass and energy balances across the system. |

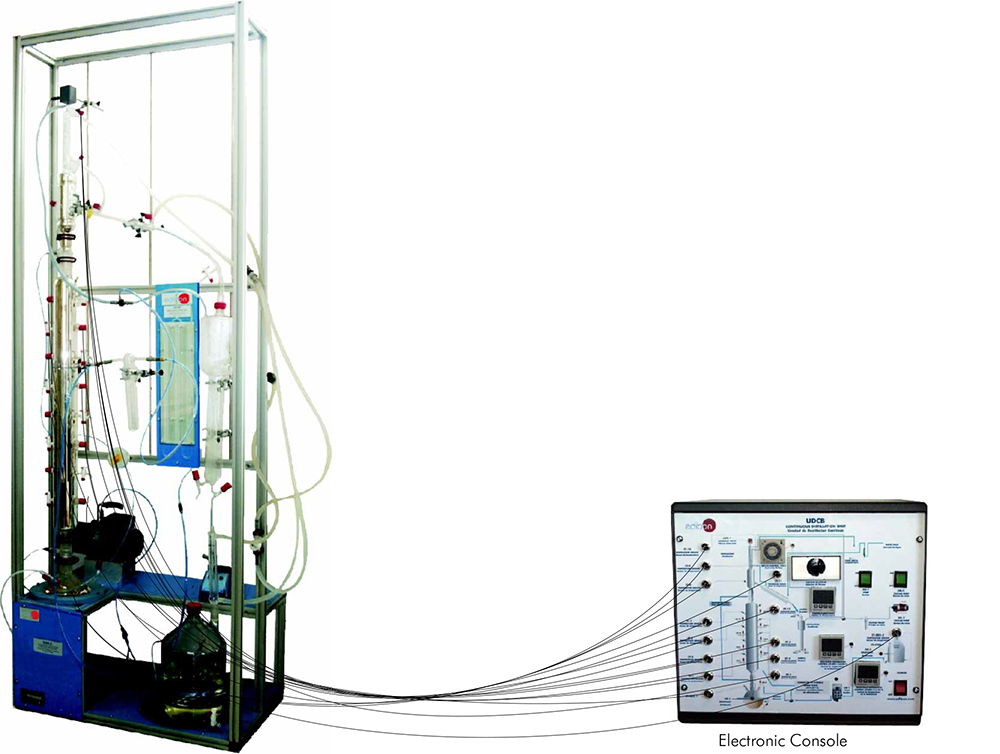

| Anodized aluminium structure and panels in painted steel (epoxy paint). |

| Main metallic elements in stainless steel. |

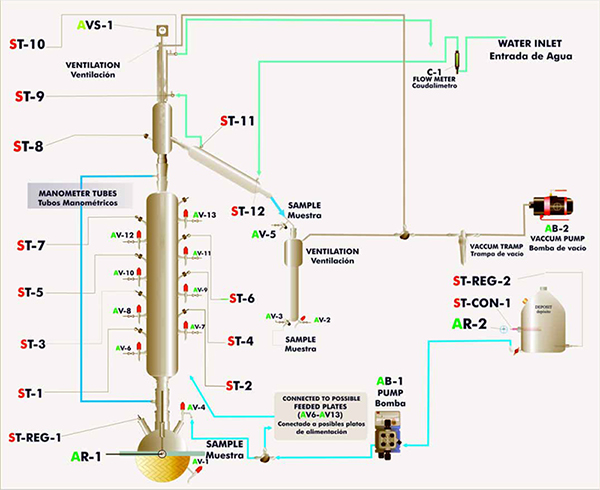

| Diagram in the front panel with similar distribution to the elements in the real unit. |

|

Sieve Plates Column with 8 plates with temperature taking (sensor) and sample in every plate. 50 mm. internal diameter and 1000 mm. length. Vacuumed, silver-plated and double transparent band for vision. |

| The column can work both continuously and discontinuously. |

| Column head with temperature taking, conical output for distilled product and ball refrigerator. |

| Column head with a valve for the steam distribution. The valve operates in an electromagnetic way. |

| 2l. Boiler (with sample outputs) with heating mantle, with adjustable power (max. power: 500 watt.). |

| 2l. Distillation collector of graduated glass. |

| Liebig-west coolant. |

|

Feeding system in continuous with preheating (heating resistance) at the specified temperature and a pump that provides a maximum flow of 3.81 l/min. |

| Feed vessel, 10 l. capacity. |

| Adjustable vacuum pump that allows to decrease the atmospheric pressure to 0.8 bar. |

| Temperature measurement system. 12 Temperature sensors (”J” type). |

| Flow meter. |

| Manometer tubes. |

| Working temperature : ambient temperature up to 125ºC. |

| Solenoid valve. |

|

Electronic Console: |

| Cables and accessories,for normal operation. |

|

Manuals: |

|

- Electrical supply: 220 V./50Hz. or 110V./60Hz. |

| Unit |

- Dimensions: 900 x 600 x 2800 mm. approx. |

| Electronic Console |

- Dimensions: 490 x 450 x 470 mm. approx. |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.