EDIBON SCADA System

EDIBON SCADA System

|

Temperature Process Control:

|

pH Process Control:

|

|

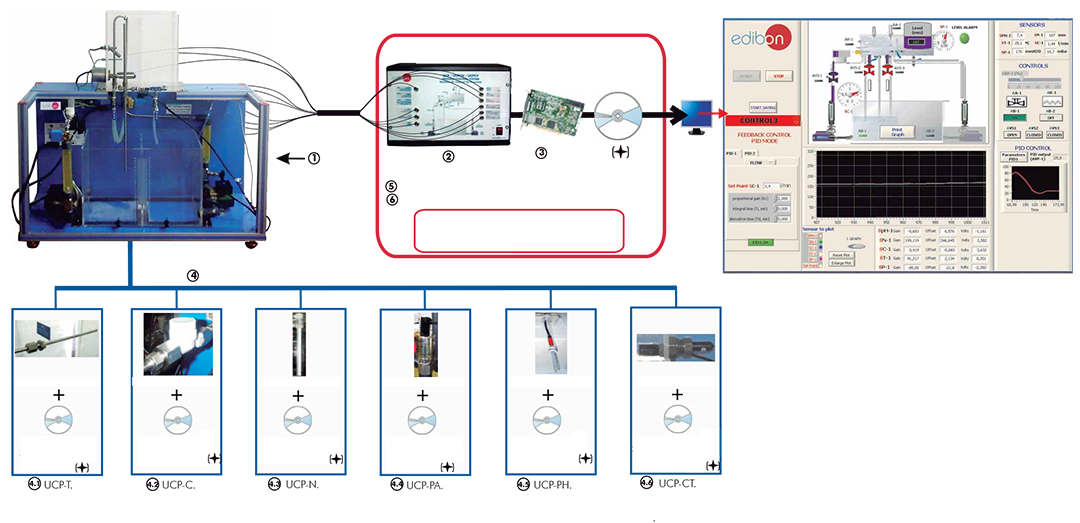

1. UCP-UB. Unit: This unit is common for all Sets for Process Control type “UCP” and can work with one or several sets. Anodized aluminum structure, with painted steel panels. Diagram in the front panel. A transparent main tank and collector with an orifice in the central dividing wall. (2 x 25 dm3), and drainage in both compartments. A transparent dual process tank (2 x 10 dm3), interconnected with an orifice and a ball valve and an overflow in the dividing wall; a graduate scale and a threaded drain of adjustable level with bypass. |

|

2. UCP/CIB.Control Interface Box : This is common for all Sets for Process Control type “UCP” and can work with one or several sets. With process diagram in the front panel. The unit control elements are permanently |

| 3. DAB. Data Acquisition Board:

PCI Express Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs. Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/ Outputs. |

|

4. Sets (sensor and elements + computer control software)used in the base unit: (These Sets will be supplied and installed in the Base Unit and ready for working)

4.1 UCP-T. Set for Temperature Process Control:

4.2 UCP-C. Set for Flow Process Control:

4.3 UCP-N. Set for Level Process Control: 0-300mm level sensor (of capacitive immersion, 4-20mA).

4.4 UCP-PA. Set for Pressure Process Control: Computer Control Software for Pressure Process Control.(#)

4.5 UCP-PH. Set for pH Process Control:

4.6 UCP-CT. Set for Conductivity and TDS (Total Dissolved Solids) Process Control: |

| 5. Cables and Accessories, for normal operation. |

|

6. Manuals: This unit is supplied with 8 manuals. |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.