Unit: TTLFC. Fluidisation and Fluid Bed Heat Transfer Unit Unit: TTLFC. Fluidisation and Fluid Bed Heat Transfer Unit PID CONTROL

Unit: TTLFC. Fluidisation and Fluid Bed Heat Transfer Unit Unit: TTLFC. Fluidisation and Fluid Bed Heat Transfer Unit PID CONTROL1.- Observation of the behaviour in a fluidised bed of a wide range of granular materials, from onset of fluidisation to entrainment.

2.- Study of the behaviour of particles in a bed when an ascendant airflow is applied.

3.- Study of the relation between bed height, drop pressure and ascendent air velocity through the particle bed.

4.- Investigation of the effect of distributor design on bed behaviour.

5- Measurement of air flow and pressure drop through a variety of granular materials.

6.- Demonstration of separation by particle size and density.

7.- Study of the variation of the heat transfer coefficient in a fluidised bed by effect of the following parameters: Superficial velocity. Depth of immersion of the hot surface in the bed. Particle size.

8.- Sensors calibration. Other possible practices:

9-27.- Practices with PLC.

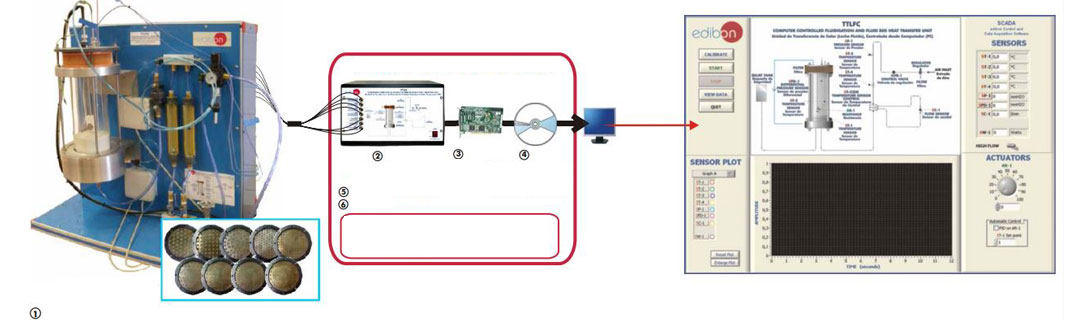

1. TTLFC. Unit:

The TTLFC unit has been designed to provide visual and quantitative results related to the flow of air through both a packed and a fluidised bed of granular material. Clear experimental set-up for investigations of the heat transfer in a fluidised bed. It also provides quantitative results related to heat transfer in a fluidised bed.

Anodized aluminium structure and panels in painted steel.

Diagram in the front panel with similar distribution to the elements in the real unit.

Bed chamber: crystal cylinder in which is contained a granular material through which a fluid (air) passes and which feeds the bed through a distributor in its lower part. It has two temperature sensors, and two stainless steel couplings that carry a heating resistance (computer controlled) and the pressure probes.

Granular material (glass perls): 1 Kg. (170-300 microns) and 1 Kg. (250-420 microns).

Heating element (150 W), computer controlled: cylindrical heating with a cooper-covered resistance. It has two temperature sensors on the surface, one indicates the surface temperature, and the other is associated to a controller that prevents the temperature from exceeding a pre established value.

Distributor: in the lower part of the bed chamber. 9 different types of distributors supplied with the unit.

Air filter. Regulator and filter. Pressure relief tank. Flow sensor. Pressure sensor. Differential pressure sensor. Temperature sensor in the chamber air intake. Power measurement from the computer (PC).

2. TTLFC/CIB. Control Interface Box :

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process. Calibration of all sensors involved in the process. Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time PID control with flexibility of modifications from the computer keyboard of the PID parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board:

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs. Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs.

4. TTLFC/CCSOF. PID Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second. It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation.

6. Manuals: This unit is supplied with 8 manuals.

Dimensions (approx.) = Unit: 750 x 500 x 750 mm. Weight: 50kg.

Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.