PID CONTROL

PID CONTROL1.- Measurement of the relationship between temperature and pressure of the saturated vapour in the loop.

2.- Understanding the origin and use of steam tables.

3.- Understanding saturation curves.

4.- To study the characteristics of a two phase fluid.

5.- U s i n g a t h r o t t l i n g calorimeter to determine the quality of wet steam. Saturation Loop:(6 to 13)

6.- Observation of the patterns of boiling at the surface of the water.

7.- To study the concept of a saturation line.

8.- Gauge and absolute pressures.

9.- Measurement of the temperature of saturated steam over the range of pressures 0 to 7 bar gauge and comparison of the saturation curves obtained.

10.-Temperature scales.

11.-Observation of the effect of rate of response on the accuracyofmeasurement.

12.-To study the characteristic behaviour of a two phase fluid.

13.-The describing equation and linearisation. Throttling Calorimeter:(14 to 18)

14.-Determination of the condition of the wet steam (quality of the steam) produced by the saturation pressure unit at different operating pressures.

15.-The two property rule.

16.-The difference in enthalpy between phases-enthalpy of vaporisation.

17.-Use of steam tables.

18.-Use of the steady flow energy equation.

Other possible practices:

19.-Sensors calibration.

20-38.- Practices with PLC.

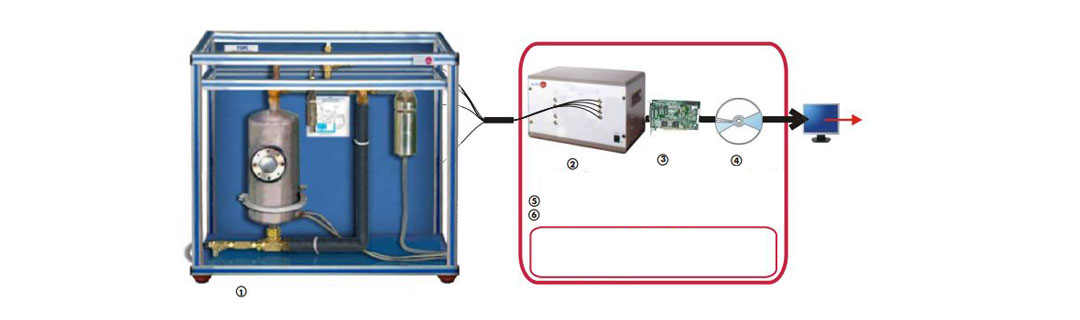

1. TSPC. Unit:

The Saturation Pressure Unit has been designed to introduce students to how the temperature of water behaves at its boiling point variation in the absolute pressure. The quality of steam exiting the unit can be determined by a throttling calorimeter connected at the point of discharge. It allows the measurement of the relationship between temperature and pressure of the saturated vapour in the loop.

Boiler vessel and pipe loop with a pressure relief valve to limit the operation pressure and a pressure sensor that indicates the pressure in the unit for safe operation. Sight glass in the bolier allows observation of the boiling patterns. Control of heat input to the boiler using variable power control.

2 Electric heating elements (500W approx. each one) for heating the boiler, with variable power control and over-temperature protection. A throttling calorimeter allows the condition of the saturated steam to be determined by measuring the temperature of the steam following throttling to atmospheric pressure.Temperature sensors. Pressure in the loop is measured using and pressure sensor.

2. TSPC/CIB. Control Interface Box:

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process.

Calibration of all sensors involved in the process. Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time PID control with flexibility of modifications from the computer keyboard of the PID parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board:

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs.

Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs.

4. TSPC/CCSOF. PID Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second. It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation.

6. Manuals: This unit is supplied with 8 manuals.

Dimensions (approx.) =Unit: 700 x 400 x 600 mm. Weight: 40 Kg.

Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.