PID CONTROL

PID CONTROL1.- Understanding the meaning of recycle. Steady state mass balances: (2)

2.- Demonstrating that whatever the recycle rate, the inlet flow rate always equals the outlet flow rate. Unsteady state heat balances: (3-6)

3.- Determining the unit response when the electrical heater is switched on at different through flow rates.

4.- Determining the effect of a changes in the inlet flow.

5.- Determining the response when the electrical heater is switched off at different through flow rates.

6.- Determining the effect of recycle with no through flow. Steady state heat balances: (7-8)

7.- With the electrical heater switched on and at a fixed water flow rate at the inlet we can check that different reclycled flow incites a variation in the outlet temperature.

8.- With the electrical heater switched on, the difference between inlet temperature and outlet temperature can be used to determine the heat quantity absorbed in the recycle loop.

9.- Use of the steady flow energy equation for the overall system.

10.-Use of the steady flow energy equation for the mixing process.

11.-Effects on response rates to parameter changes in recycle flow.

12.-Effects on response rates to parameter changes in through flow.

13.-Effects on response rates to parameter changes in loop volume.

14.-Effects on response rates to parameter changes in heater power.

Other possible practices: 15.-Sensors calibration.

16-34.- Practices with PLC.

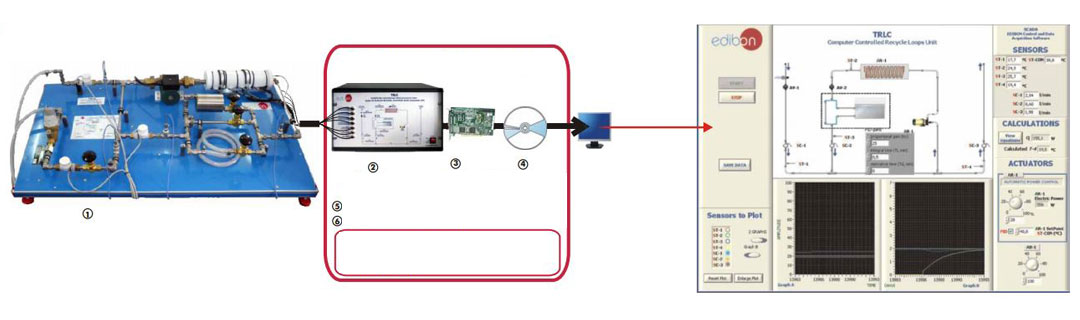

1. TRLC Unit:

Unit to demonstrate, both visually and experimentally, how a recycle loop works. It has a lot of teaching applications of which the carried out of mass and energy balances under steady and unsteady state conditions is emphasized.

Diagram in the front panel with similar distribution to the elements in the real unit.

Water inlet pipe, which incorporates a temperature sensor and a flow sensor. Water inlet flow regulation valve. Pressure regulation valve, to avoid overpressures.

Recycle loop, composed of: recirculation pump (computer controlled); heating resistance (2000W) that works with a PID control over the temperature sensor; protection thermostat for the heating resistance; water control valve; 3 temperature sensors and flow sensor.

Water outlet pipe, which incorporates a temperature sensor and a flow sensor.

Different volumes of recycle loop, usable without having to be dismounted.

2. TRLC/CIB. Control Interface Box:

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process.

Calibration of all sensors involved in the process. Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time PID control with flexibility of modifications from the computer keyboard of the PID parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board:

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs.

Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs.

4. TRLC/CCSOF. PID Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data.

Sampling velocity up to 250,000 data per second. It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation.

6. Manuals: This unit is supplied with 8 manuals.

Dimensions (approx.) = Unit: 1110 x 630 x 300 mm. Weight: 40kg.

Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.