PID CONTROL

PID CONTROL1.- Demonstration of the increase in heat exchanger effectiveness due to increasing the number of tube passes at constant flow rates.

2.- Visual demonstration of filmwise condensation and nucleate boiling.

3.- Measurement of the effect of coolant flow velocity and the number of tube passes on pressure drop.

4.- Investigation of the saturation pressure/temperature relationship for water at low pressures.

5.- Investigation of the effect of increasing flow velocity and number of tube passes on the overall heat transfer coefficient. Other possible practices:

6.- Sensors calibration.

7-25 .- Practices with PLC.

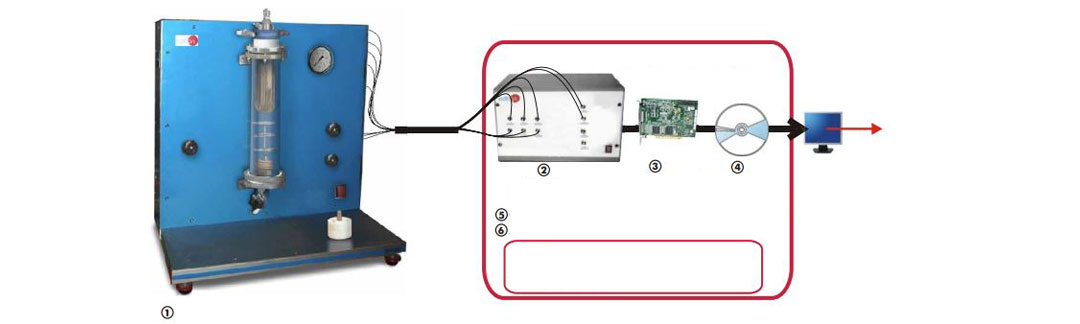

1. TIVAC. Unit:

This unit has been designed to provide results (visual and quantitative) related to heat transfer in shell and tube type water cooled condensers.

Anodized aluminium structure and panels in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

Steam to water shell and tube condensing heat exchanger having its own 3KW steam generator and four U tube condensers. Three interchangeable manifolds allowing single, double or four pass operation. Heater. Circulating pump.

Temperature sensors to measure steam chamber and condenser inlet and outlet temperatures. Pressure sensor to measure pressure drop across condenser. 2 Flow sensors to measure total water flow through condenser and water flow from mains.

Pressure sensor for steam chamber pressure. Safety elements as pressure relief valve, pressure switch etc.

2. TIVAC/CIB. Control Interface Box:

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process. Calibration of all sensors involved in the process.

Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time PID control with flexibility of modifications from the computer keyboard of the PID parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board:

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs. Sampling rate up to:

250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs.

4. TIVAC/CCSOF. PID Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second. It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation.

6. Manuals: This unit is supplied with 8 manuals.

Dimensions (approx.) = Unit: 700 x 600 x 750 mm. Weight: 50 Kg. Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.