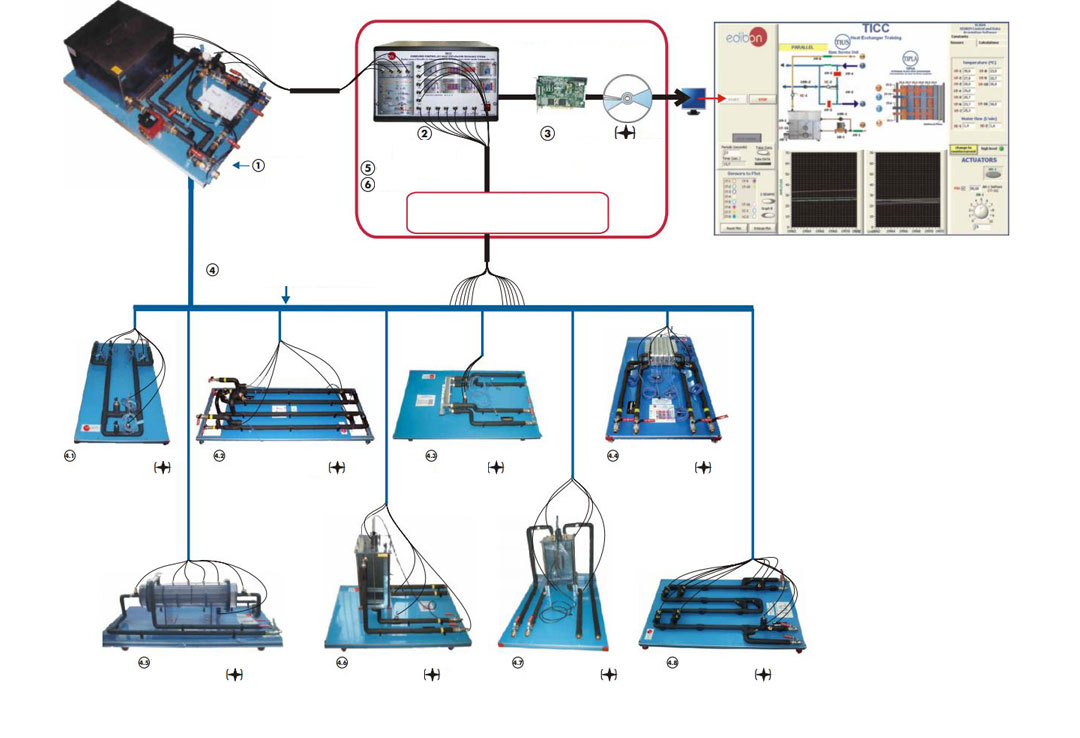

SCADA EDIBON Computer Control System Heat Exchangers available to be used with the Base Service Unit: Control

SCADA EDIBON Computer Control System Heat Exchangers available to be used with the Base Service Unit: ControlPractices to be done with the Extended Concentric Tube Heat Exchanger (TITCA): Practices to be done with the Plate Heat Exchanger (TIPL): Practices to be done with the Extended Plate Heat Exchanger (TIPLA):

1.- Global energy balance in the exchanger and the study of losses.

2.- Exchanger effectiveness determination. NTU Method.

3.- Study of the heat transfer under of countercurrent and parallel flow conditions.

4.- Flow influence in the heat transfer. Reynolds number calculation.

5.- Control system: Temperature sensors calibration.

6.- Control system: Flow sensors calibration.

7.- Study of the hysteresis of the flow sensor.

8-26.- Practices with PLC.

27.-Global energy balance in the exchanger and the study of losses.

28.-Exchanger effectiveness determination. NTU Method.

29.-Study of the heat transfer under of countercurrent and parallel flow conditions.

30.-Flow influence in the heat transfer. Reynolds number calculation.

31.-Control system: Temperature sensors calibration.

32.-Control system: Flow sensors calibration.

33.-Study of the hysteresis of the flow sensor.

34-52.- Practices with PLC.

53.-Global energy balance in the exchanger and the study of losses.

54.-Exchanger effectiveness determination. NTU Method.

55.-Study of the heat transfer under of countercurrent and parallel flow conditions.

56.-Flow influence in the heat transfer. Reynolds number calculation.

57.-Control system: Temperature sensors calibration.

58.-Control system: Flow sensors calibration.

59.-Study of the hysteresis of the flow sensor.

60-78 .- Practices with PLC.

79.-Global energy balance in the exchanger and the study of losses.

80.-Exchanger effectiveness determination. NTU Method.

81.-Study of the heat transfer under of countercurrent and parallel flow conditions.

82.-Flow influence in the heat transfer. Reynolds number calculation.

83.-Control system: Temperature sensors calibration.

84.-Control system: Flow sensors calibration.

85.-Study of the hysteresis of the flow sensor.

86-104.- Practices with PLC.

Practices to be done with the Shell & Tube Heat Exchanger (TICT):

105.-Global energy balance in the exchanger and the study of losses.

106.-E x c h a n g e r e f f e c t i v e n e s s determination. NTU Method.

107.-Study of the heat transfer under of countercurrent and parallel flow conditions.

108.-Flow influence in the heat transfer. Reynolds number calculation.

109.-Control system: Temperature sensors calibration.

110.-Control system: Flow sensors calibration.

111.-Study of the hysteresis of the flow sensor.

112-130.- Practices with PLC. Practices to be done with the Jacketed Vessel Heat Exchanger (TIVE):

131.-Global balance of energy in the exchanger and losses study.

132.-Determination of the exchanger effectiveness. NTU Method.

133.-Influence of the flow in the heat transfer. Calculation of the number of Reynolds.

134.-Influence of the stirring of the vessel on the heat transfer when operating in batches.

135.-Influence of the vessel's water volume on the heat transfer when operating in batches.

136.-Control system: Temperature sensors calibration.

137.-Control system: Flow sensors calibration.

138.-Study of the hysteresis of the flow sensor.

139-157.- Practices with PLC. Practices to be done with the Coil Vessel Heat Exchanger (TIVS):

158.-Global balance of energy in the exchanger and the study of losses

159.-Determination of the exchange effectiveness. NTU Method.

160.-Influence of the flow in the heating transfer. Calculation of Reynolds number.

161.-Influence of the stirring vessel in the heat transfer with operation in batches.

162.-Influence of the water volume in the vessel about the heat transfer with operation in batches.

163.-Control System: Temperature sensors calibration.

164.-Control System: Flow sensors calibration.

165.-Study of the hysteresis of the flow sensor

166-184.- Practices with PLC.

Practices to be done with the Turbulent Flow Heat Exchanger (TIFT):

185.-Global energy balance in the exchangers and loss study.

186.-Determination of the exchanger effectiveness. NTU Method.

187.-Study of the heat transfer in crosscurrent and parallel flow conditions.

188.-Flow influence in heat transfer. Reynolds number calculation.

189.-Obtaining of the correlation that relates Nusselt number with Reynolds number and Prandtl number.

190.-Obtaining of the heat transfer coefficients by convection.

191.-Control system: Temperature sensors calibration.

192.-Control system: Flow sensors calibration.

193.-Study of the hysteresis in the flow sensors.

194-212.- Practices with PLC.

4.1. TITC. Concentric Tube Heat Exchanger:

This Concentric Tube Heat Exchanger allows the study of heat transfer between hot water flowing through an internal tube and cold water flowing in the ring area lying between the internal and external tubes. This exchanger allows measuring hot and cold water temperatures in different points of the exchanger.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit The exchanger is formed by two concentric copper tubes with hot water circulating through the interior tube and cold water circulating in the ring space.

This exchanger has 2 equal sections of 500 mm each one, where heat transfer takes place.

Exchange length: L = 2 x 0.5 = 1 m.

Internal tube: Internal diameter: Dint = 16 • 10-3 m. External diameter: Dext = 18 • 10-3 m. Thickness = 10-3 m. Heat transfer internal area: Ah = 0.0503 m2 . Heat transfer external area: Ac = 0.0565 m2.

External tube: Internal diameter: Dint = 26 • 10 m. External diameter: Dext = 28 • 10 m. Thickness = 10 m.

6 Temperature sensors: 3 temperature sensors for measuring cold water temperature and 3 temperature sensors for

measuring hot water temperature.

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Concentric Tube Heat Exchanger (TITC).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed. It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1100 x 630 x 320 mm. Weight: 20 Kg.

4.2. TITCA. Extended Concentric Tube Heat Exchanger:

This Extended Concentric Tube Heat Exchanger allows the study of heat transfer between hot water flowing through an internal tube and cold water flowing in the ring area lying between the internal and external tubes. This exchanger allows measuring hot and cold water temperatures in different points of the exchanger.

TITCA is a more sophisticated unit than TITC, with four longer tube sections, giving four times the overall heat transfer area and three interim temperature measurement points (temperature sensors) in each fluid stream.

This exchanger has sufficient heat transfer area for demonstrating the typical counter current flow conditions where the outlet of the heated stream is hotter than the outlet of the cooled stream.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

The exchanger is formed by two concentric copper tubes with hot water circulating through the interior tube and cold water circulating in the ring space.

This exchanger has 4 sections of 1000 mm each one, where heat transfer takes place.

Exchange length: L=4x1=4 m.

Internal tube: Internal diameter: Dint = 16 • 10-3 m. External diameter: Dext = 18 • 10-3 m. Thickness = 10-3 m. Heat transfer internal area: Ah = 0.0503 m . Heat transfer external area: A c= 0.0565 m . 2 2

External tube: Internal diameter: Dint = 26 • 10-3 m. External diameter: Dext = 28 • 10-3 m. Thickness = 10-3 m.

10 Temperature sensors: 5 temperature sensors for measuring cold water temperature and 5 temperature sensors for measuring hot water temperature.

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Extended Concentric Tube Heat Exchanger (TITCA).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed. It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1500 x 700 x 320 mm. Weight: 30 Kg.

4.3. TIPL. Plate Heat Exchanger:

This Plate Heat Exchanger allows the study of heat transfer between hot and cold water through alternate channels formed between parallel plates. The exchanger allows measuring cold and hot temperatures at the inlet and outlet of the exchanger.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

Formed by corrugated stainless steel plates. This can be dismantled to observe its structure.

4 ports or connections of input and output of hot and cold water.

Max. flow: 12m /h. Max. work pressure: 10 bar. Max. work temperature: 100 C. Minimum work temperature: 0 C. Max. 3 o o number of plates: 20. Internal circuit capacity: 0.176 l. External circuit capacity: 0.22 l. Area: 0.32m . 2 4 Temperature sensors: 2 temperature sensors for measuring cold water temperature (inlet and outlet) and 2 temperature sensors for measuring hot water temperature (inlet and outlet).

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Plate Heat Exchanger (TIPL).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed. It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1100 x 630 x 320 mm. Weight: 20 Kg.

4.4 TIPLA. Extended Plate Heat Exchanger:

This Extended Plate Heat Exchanger allows the study of heat transfer between hot and cold water through alternate canals formed between parallel plates. The exchanger allows measuring cold and hot temperatures in different points of the exchanger.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

Formed by corrugated stainless steel plates. This can be dismantled to observe its structure.

4 ports or connections of input and output of hot and cold water.

Max. flow: 12m /h. Max. work pressure: 10 bar. Max. work temperature: 100 C. Minimum work temperature: 0 C. Max. 3 o o number of plates: 20. Internal circuit capacity: 0.176 l. External circuit capacity: 0.22 l. Area: 0.32m . 2 10 Temperature sensors: 5 temperature sensors for measuring cold water temperature (inlet, outlet and interim positions) and 5 temperature sensors for measuring hot water temperature (inlet, outlet and interim positions).

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Extended Plate Heat Exchanger (TIPLA).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed. It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1200 x 700 x 320 mm. Weight: 25 Kg.

4.5. TICT. Shell & Tube Heat Exchanger:

It consists of a group of tubes inside the heat exchanger. The hot water flows through the internal tubes and cooling water circulates through the space between the internal tubes and the shell. There are traverse baffles placed in the shell to guide the cold water maximize the heat transfer.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

Formed by tubes of stainless steel with hot water circulating in the interior.

4 segmented baffles located transversal in the shell.

Exchange length of the shell and each tube: L = 0.5m.

Internal tube (21 tubes): Internal diameter: D = 8 • 10-3 m. External diameter: D = 10 • 10-3 m. Thickness = 10-3 m. int ext Internal heat transfer area: Ah = 0.0126 m2 . External heat transfer area : Ac = 0.0157m2 .

Shell: Internal diameter: Dint,c = 0.148 m. External diameter: Dext,c = 0.160 m. Thickness = 6 • 10-3 m.

7 Temperature sensors for measuring cold and hot water temperatures in different points of the exchanger.

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Shell & Tube Heat Exchanger (TICT).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed.It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1100 x 630 x 400 mm. Weight: 30 Kg.

4.6. TIVE. Jacketed Vessel Heat Exchanger:

This Jacketed Vessel Heat Exchanger allows the study of heat transfer between hot water flowing through a jacket and the cold water contained in a vessel. It can work in continuous supply or in a batch process (heating of a constant mass of water containing in a vessel). The exchanger allows measuring temperatures at the inlet and outlet of the exchanger in cold as well as in hot water.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

Constituted of a vessel. Vessel total volume: 14 l. Interior vessel volume: 7 l. approx. Jacket volume: 7 l. approx.

An overflow or a pipe that allows the exit of the water in the vessel through its upper part to maintain a constant flow during the process with continuous supply.

A jacket that surrounds the vessel through where hot water flows.

An electric stirrer, range between 50 and 300 rpm.

5 Temperature sensors: 3 temperature sensors for measuring cold water temperature and 2 temperature sensors for measuring hot water temperature.

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Jacketed Vessel Heat Exchanger (TIVE).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed. It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1100 x 630 x 700 mm. Weight: 35 Kg.

4.7. TIVS. Coil Vessel Heat Exchanger:

This heat exchanger allows the study of heat transfer between hot water flowing through a coil and cold water contained in the vessel. It can work in continuous supply or in a batch process.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

Formed by a pvc-glass vessel, volume: 14 l.

An overflow or pvc-glass tube lets the output of water from the vessel in the upper part in order to maintain the flow constant A copper coil where the water circulates: D = 4.35 mm. D = 6.35 mm. int ext An electric stirrer, range between 50 and 300 rpm.

5 Temperature sensors: 3 temperature sensors for measuring cold water temperature and 2 temperature sensors for measuring hot water temperature.

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Coil Vessel Heat Exchanger (TIVS).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed. It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1100 x 630 x 700 mm. Weight: 30 Kg.

4.8. TIFT. Turbulent Flow Heat Exchanger:

This Turbulent Flow Heat Exchanger let us the heat transfer study between hot water that circulates through an internal tube and cold water that flows through the annular zone between the internal and the external tubes. This exchanger let us to measure cold water and hot water temperatures in different points of the exchanger.

Anodized aluminium structure and panel in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit.

Formed by two copper concentric tubes with hot water circulating through the internal tube and cold water circulating through the annular space.

The exchanger has 4 equal sections of 500 mm each one, where the heat transfer takes place.

Exchange length: L = 4 x 0.5 = 2 m.

Internal tube: Internal diameter: Dint = 8 • 10 -3m. External diameter: Dext = 10 • 10-3 m. Thickness = 10 m. Internal heat transfer area: A h= 0.0377 m 2. External heat transfer area: Ac = 0.0471 m 2. External tube: Internal diameter: Dint,c 13 • 10 -3m. External diameter: Dext,c 15 • 10-3 m. Thickness = 10-3 m. 12 Temperature sensors.

Easy connection with the Base Service Unit.

Computer Control Software:

Computer Control+Data Acquisition+Data Management Software for Turbulent Flow Heat Exchanger (TIFT).

Flexible, open and multicontrol software. Analog and digital PID control. Menu for PID and set point selection required in the whole work range. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second guaranteed. It allows the registration of the alarms state and the graphic representation in real time.

This unit is supplied with 8 manuals.

Dimensions (approx.) = 1100 x 630 x 350 mm. Weight: 20 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.