PID CONTROL

PID CONTROL1.- Observation of: Single-phase liquid flow. Sub-cooled boiling. Bubbly flow. Slug regime. Annular flow. Film boiling. Drop flow (mist). Single-phase vapour flow.

2.- Demonstration of a heating process accompanied by vapour formation within a tube, including: Circulation promoted by natural convection. Nucleation in sub-cooled and saturated liquid. Convective heat transfer to sub-cooled liquid. Slugging. Droplet entrainment. Annular flow. Complete dry out to superheated vapour.

3.- Demonstration of effect of air in condensers.

4.- Demonstration of two phase flow with increasing vapour content.

5.- Effect of flow rate on the evaporation process.

6.- Effect of temperature on the evaporation process.

7.- Effect of pressure on the evaporation process.

8.- Relationship between pressure and temperature.

9.- Film condensation.

Other possible practices:

10.-Sensors calibration.

11-29.-Practices with PLC.

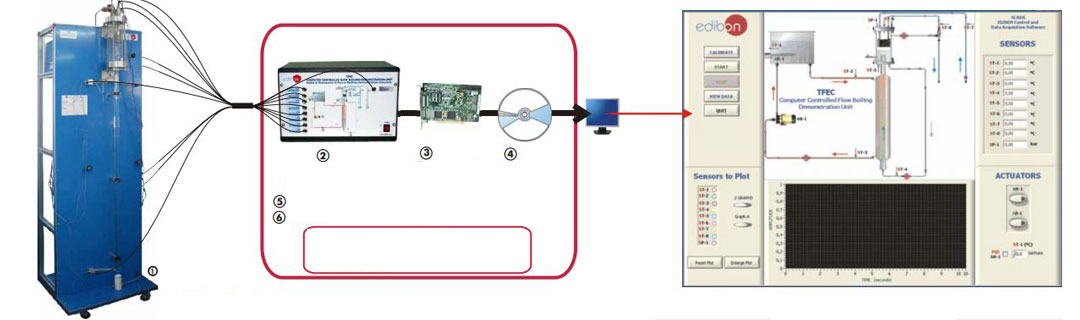

1. TFEC. Unit:

Anodized aluminium structure and panels in painted steel. Diagram in the front panel with similar distribution to the elements in the real unit. Experiment visualisation tube of 1500 mm. length composed by two glass concentric tubes. Refrigerant control valve. Condensing chamber. Security valve, to avoid overpressures. Condensate coil. Thermostatic bath, that heats the water that flows by the experimental tube (heating resistance of 600W, computer controlled). Centrifugal pump for hot water impulsion, computer controlled. Water control valve regulates the water flow that enters in the condensate coil. Water jet pump for extracting the air and controlling the refrigerant pressure.

8 Temperature sensors, distributed along the process to know the heat transfers occurred.

1 Absolute pressure sensor. Water flow meter. Drain and security valve.

This unit has been designed for using SES36 refrigerant gas, free of CFC´s, compatible with the Environment.

2. TFEC/CIB. Control Interface Box:

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process.

Calibration of all sensors involved in the process. Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time PID control with flexibility of modifications from the computer keyboard of the PID parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board:

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs.

Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs.

4. TFEC/CCSOF. PID Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data.

Sampling velocity up to 250,000 data per second. It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation.

6. Manuals: This unit is supplied with 8 manuals.

Dimensions (approx.) = Unit: 750 x 700 x 2100 mm. Weight: 70 Kg.

Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.