SCADA EDIBON Computer Control System Unit: TAAC. Air Conditioning Laboratory Unit Control

SCADA EDIBON Computer Control System Unit: TAAC. Air Conditioning Laboratory Unit Control1.- Demonstration of the processes and components used in heating, cooling, humidification, de-humidification of an airstream.

2.- Obtaining of the steam generator efficiency curve.

3.- Energy balance in the steam generator.

4.- Efficiency determination of the preheating resistance.

5.- Preheating effect in an air conditioning installation.

6.- Dehumidification process study.

7.- Material balance in the evaporator.

8.- Energy balance in the evaporator.

9.- Re-heat effect.

10.-Experimental determination of the air specific heating capacity. Other possible practices:

11.-Psychrometric chart.

12.-Example of the air properties determination.

13.-Usage of psychrometric chart.

14.-Determination of the airflow.

15.-Temperature sensors calibration.

16.-Pressure sensors calibration.

17.-Determination of a PWM controller adjustment parameters.

18.-Properties of the Refrigerant R134a.

19.-Enthalpy-Pressure diagram for the refrigerant R134a.

20-38.- Practice with PLC

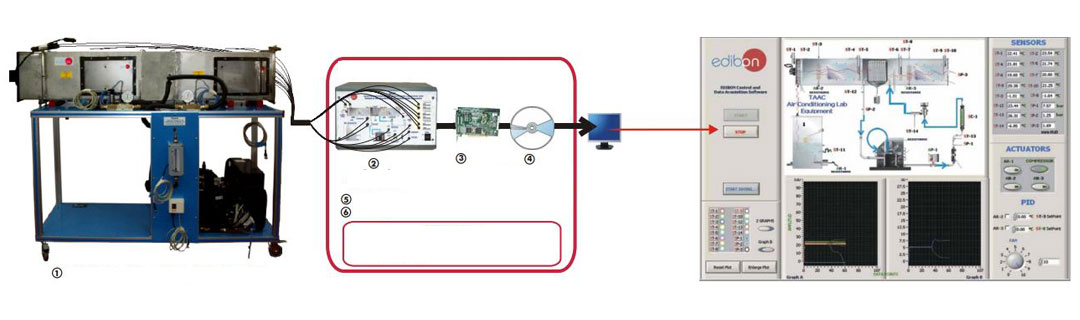

1. TAAC. Unit:

This unit has as objective to introduce the student in the world of the air conditioning installations, as well as to study and determine the good parameters for the unit operation in function of the environmental demands (humidity, heat, temperature and refrigeration, etc).

Diagram in the front panel with similar distribution to the elements in the real unit. Tunnel of 300 x 300 x 1600 mm., made in stainless steel with 2 windows of 200 x 300 mm. to visualize the tunnel inside. 2 Electrical heating resistances (computer controlled): one of 2000W (pre-heater) to the inlet of the evaporator and other of 1000 W (re-heater) to the outlet of the evaporator. 4 Hygrometers placed along the tunnel, formed each one by 2 temperature sensors (wet and dry bulb). Fan, with speed control from computer. Evaporator. Compressor. Condenser unit. High-pressure cut-out. Filter dryer.

Sensors included:

Flow meter and refrigerant flow sensor. Temperature (11): 4 dry bulb, 4 wet bulb, 1 inlet of the evaporator, 1 outlet of the evaporator, 1 outlet of the condenser. Pressure (3): 1 sensor (outlet of the condenser), 1 sensor (inlet of the condenser), 1 differential sensor (measure of flow). 1 bourdon manometer (outlet of the condenser), 1 bourdon manometer (inlet of the evaporator), 1 bourdon manometer (outlet of the evaporator).

Psychometric chart and Enthalpy diagram of R134a.

2. TAAC/CIB. Control Interface Box:

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process. Calibration of all sensors involved in the process.

Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time PID control with flexibility of modifications from the computer keyboard of the PID parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board:

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs. Sampling rate up to:

250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs.

4. TAAC/CCSOF. PID Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second. It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation.

6. Manuals: This unit is supplied with 8 manuals.

Dimensions (approx.) =Unit: 1600 x 570 x 1500 mm. Weight: 200 Kg. Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.