Introduction

Indium oxide (In2O3) is known and widely used as a conductive transparent membrane material. This material used to be produced followed sol-gel and vapor deposition method. Those methods involves thermal treatment of raw materials. Therefore, it is important to understand the thermal properties of raw materials to improve the performance of the whole process.

By connecting a TG-DTA differential thermogravimetric analyzer with a humidifier, users can study in detail heat treatment processes for raw materials by changing partial pressure of water vapor in the measuring environment.

The compact humidifier is connected to the TG-DTA device to allow measurements in a steam environment with relative ffixed humidity.

Thanks to a polymer-type moisture sensor and a high-precision temperature sensor, the device provides very fast and stable feedback for extended measurements.

The sample used is indium acetylacetone, which is the raw material, the precursor to indium oxide. The device used is the Thermo Plus TG8121 differential weight thermal analysis system connected to the HUM-1 humidifier. The amount of sample (10 mg) is heated to 600°C at a rate of 10°C / min in a nitrogen atmosphere with controlled moisture.

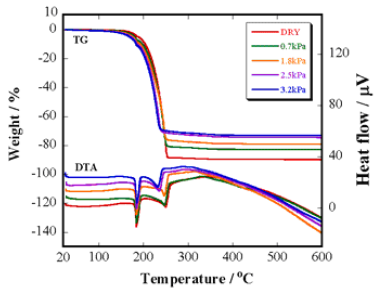

Figure 1 - Comparing the measured results of TG and DTA of indium acetylaxeton in the dry and moisture nitrogen gas environment.

Figure 1 shows the comparison of measurement results of TG and DTA of indium acetylaxeton in nitrogen gas medium with controlled humidity. When the partial pressure of vapour is increased, the reaction temperature become lower. Attach heat because the melting is less affected by partial pressure of steam. When analyzing residual components with XRD in both conditions, indium oxide was found only.

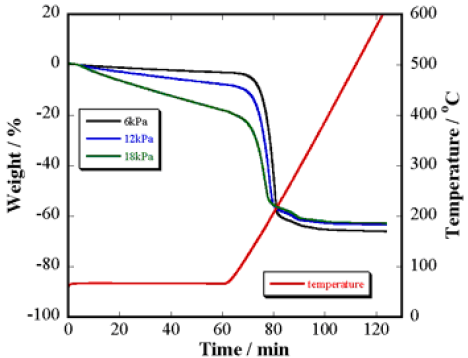

Figure 2 (a) - TG calorimetric measurement with indium acetylaxeton sample under high humidity conditions.

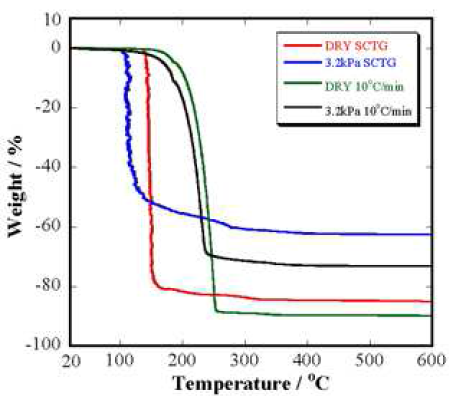

Figure 2 (b) - Sample controlled thermogravimetry (SCTG) with indium acetylaxeton sample under high humidity conditions.

Figure 2 shows a graph of TG and SCTG in high humidity conditions.