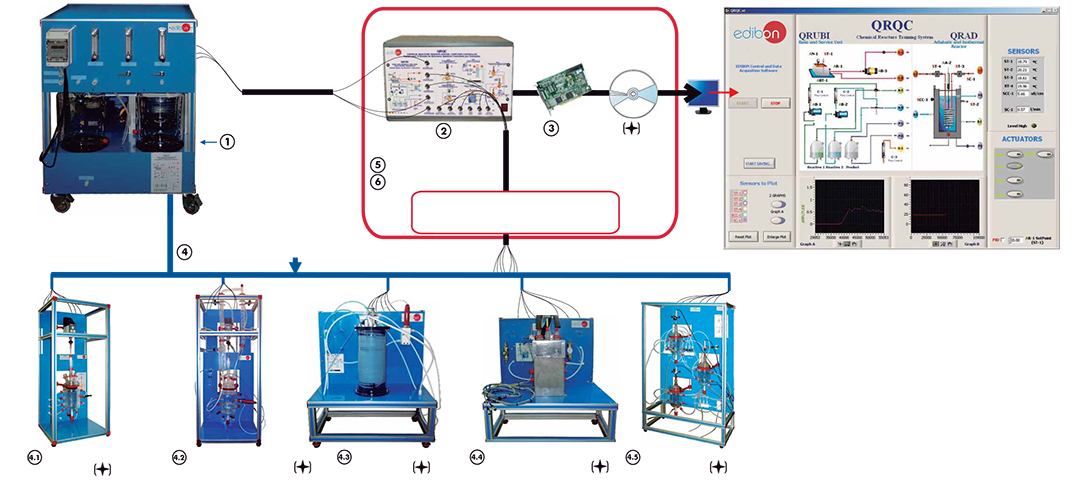

EDIBON SCADA System

EDIBON SCADA System

|

Practices to be done with the Isothermal Reactor with Distillation (QRIA/D):

34.- Determination of the ionic conductivities. Obtaining of the reaction order respect to ethyl-acetate. Initial velocity method. 37.- Discontinuous operation. Velocity Constant Computation. Constant sodium hydroxide initial concentration. Arrhenius Equation. Deviation from ideality. |

Practices to be done with the Adiabatic and Isothermal Reactor (QRAD):

100.- Determination of the ionic conductivities. 102.- Discontinuous operation. Determination of the order of the reaction referred to the sodium hydroxide. Initial velocity method. 103.- Discontinuous operation. Determination of the speed constant, the initial concentration of the sodium hydroxide is constant. Determination of the speed constant, the initial concentration of the ethyl acetate is constant. Variation of the kinetic constant when the temperature is not constant: Arrhenius equation. Comparison of the theoretical and the experimental conversion: Deviation from the ideality.

|

| Practices to be done with the Tubular Flow Reactor (QRFT):

71.- Analysis of reagents and products. |

Practices to be done with the Reactors with Stirrer in Series (QRSA):

135.- Determination of the ionic conductivities. |

|

1. QRUBI. Base Service Unit: This unit is common for Chemical Reactors and can work with one or several reactors. It supplies all the services for the operation of each reactor. 2 Dosing pumps, computer controlled. 3 Tanks of 10 l.: two for the reagents and the other for the product. 2 Flow meters for liquids. Flow meter for gas. Thermostatic bath that regulates the temperature. Level switch. A pump, computer controlled, to impel the water that comes from the thermostatic bath and goes to the reactor. Temperature sensor to get the temperature of the reactor in a continuos way. Temperature control thought the computer. Control system of the reaction. The control of the reaction is carry out by means of a conductivity cell and a conductimeter, connected to the control interface box. Dimensions (approx.)= mm. Weight: 100 Kg. |

|

2. QRQC/CIB.Control Interface Box: This is common for Chemical Reactors and can work with one or several reactors. It has a process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the PC of all parameters involved in the process. Calibration of all sensors involved in the process. Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time PID control with flexibility of modifications from the PC keyboard of the PID parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: one mechanical in the unit, electronic in the control interface, and the third one in the control software. Dimensions (approx.): 490 x 330 x 310 mm. Weight: 10 Kg |

|

3. DAB. Data Acquisition Board: PCI Express Data acquisition National Instruments board. 16 Analog inputs. Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs. |

|

4. Chemical Reactors: 4.1. QRIA. Isothermal Reactor with Stirrer:

Anodized aluminum structure and panels of painted steel.

Computer Control + Data Acquisition + Data Management Software for Isothermal Reactor with Stirrer (QRIA): It allows the registration of the alarms state and the graphic representation in real time. Dimensions (approx.)= mm. Weight: 50 Kg.

4.2. QRIA/D. Isothermal Reactor with Distillation:

Anodized aluminum structure and panels of painted steel.

4.3. QRFT. Tubular Flow Reactor:

Anodized aluminum structure and panels of painted steel.

4.4. QRAD. Adiabatic and Isothermal Reactor:

Anodized aluminum structure and panels of painted steel.

4.5. QRSA. Reactors with Stirrer in Series:

Anodized aluminum structure and panels of painted steel. |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.