● Advanced Real-Time SCADA and PID Control.

● Open Control + Multicontrol + Real-Time Control.

● Specialized EDIBON Control Software based on Labview.

● National Instruments Data Acquisition board (250 KS/s, kilo samples per second).

● Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

● Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

● Capable of doing applied research, real industrial simulation, training courses, etc.

● Remote operation and control by the user and remote control for EDIBON technical support, are always included.

● Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic & Software).

● Designed and manufactured under several quality standards.

● Optional CAL software helps the user perform calculations and comprehend the results.

● This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

The gas absorption column is a scale unit designed to study hydrodynamic and absorption processes in packed columns. This system absorbs ammonia or CO2 from a mixture with air in a watery solution that flowing down the column.

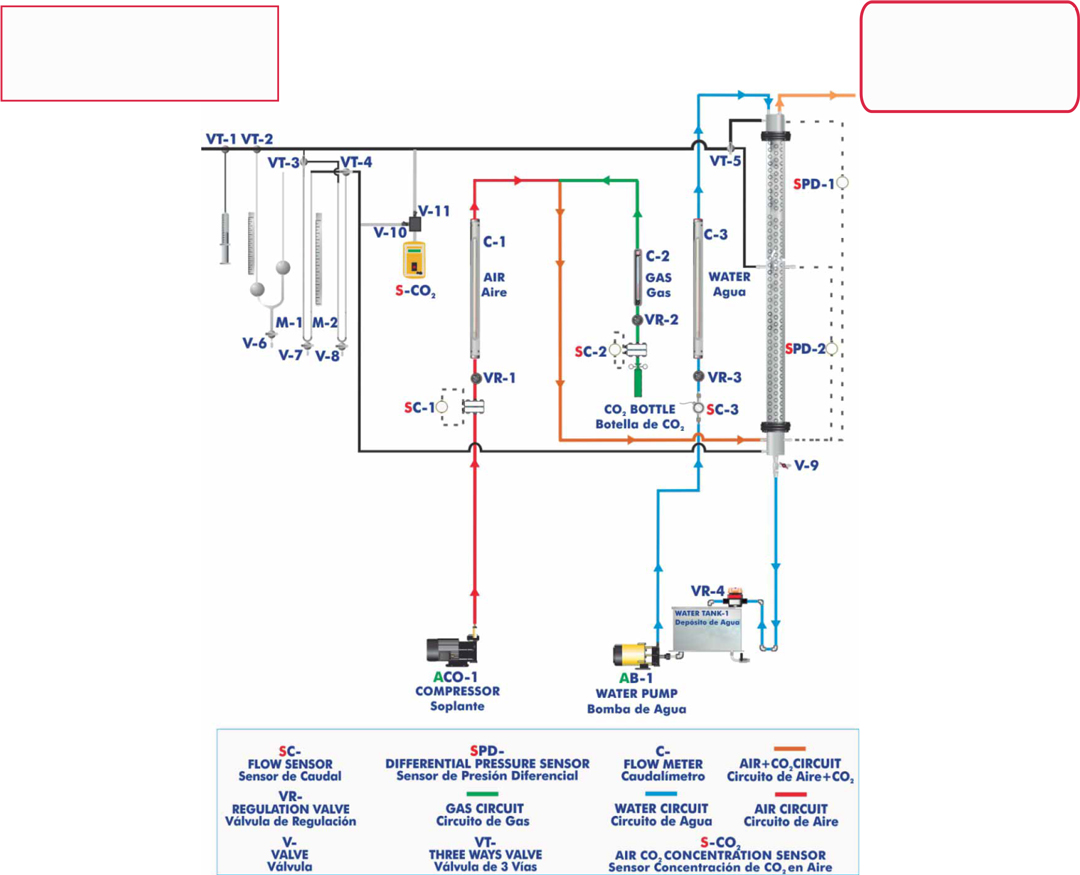

The main parts of the unit are:

● Packed column: it consists of a glass cylindrical column filled with Raschig rings. 2 differential pressure sensors measurethe pressure in different parts of the column.

● Liquid circuit (water): the liquid, that is stored in a PVC tank, is impelled towards the column by a pump. It feeds the column through its upper end using a glass diffusion shower. After crossing the column, the liquid is returned to the storage tank. The liquid flow thatarrives to the column is measured by a flow sensor and a flowmeter.

● Gas circuit (air and CO2 ): it consists of a CO2 and air (supplied by a blower) mixture current. Both gaseous currents are mixed, and later they 22 enter the base of the column through a side inlet located below the bed level, so that the gaseous mixture is an homogeneous aspossible. Both gas flows are measured by sensors and flowmeters.

● CO2 measuring system: it allows to determine the concentration of this gas in the currents originated from the upper and central parts of the column. The measurement can be performed analytically or directly with the CO2 sensor.

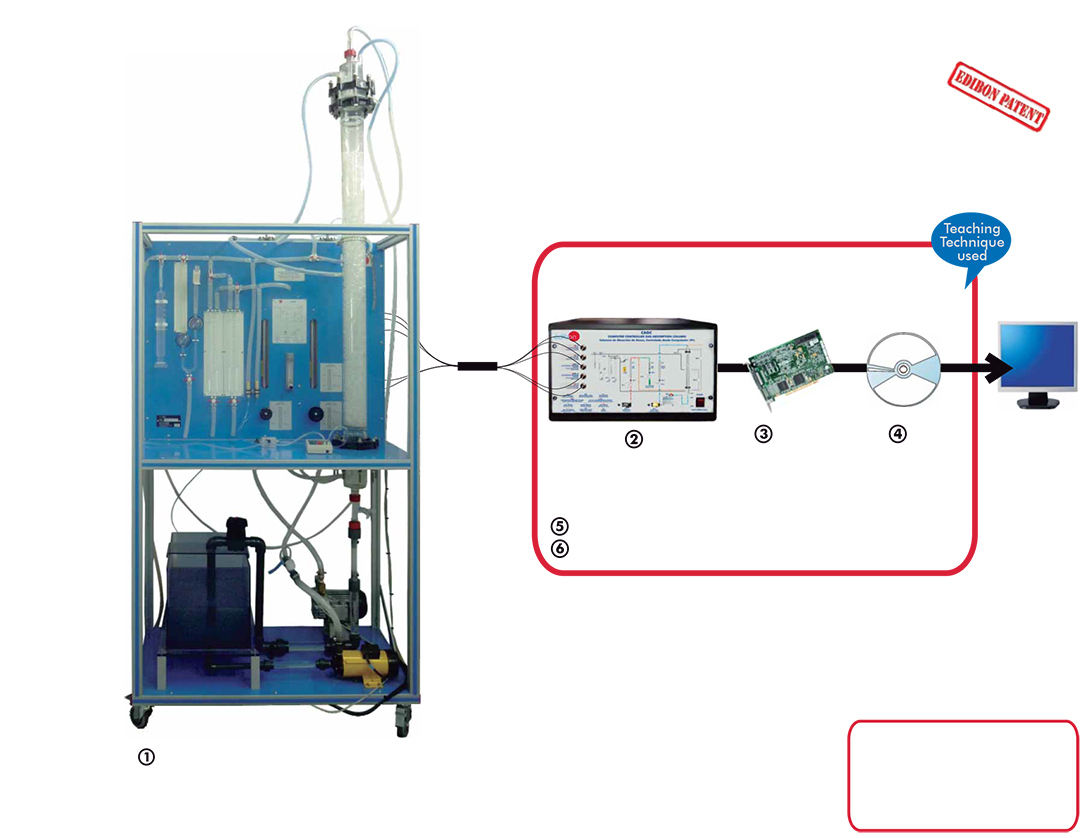

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

|

1.- Study of the basic principles of the absorption of a gas into a liquid using a packed column. To view all results in real time in the classroom by means of a projector or an electronic whiteboard. |

16.- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change thespan, gains; proportional, integral, derivate parameters; etc, inreal time. |

|

- Electrical supply: single-phase, 220V./50Hz or 110V./60Hz. |

| Unit |

- Dimensions: 1000 approx. x 740 x 2600 mm.(39.37 x 29.13 x 102.3 inches approx.) - Weight: 100 Kg. approx. (220 pounds approx.) |

| Control Interface Box |

490 x 330 x 310 mm. approx. (19.29 x 12.99 x 12.20 inches approx.). 10 Kg. approx. (22 pounds approx.). |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.