The gas absorption column is a scale unit designed to study hydrodynamic and absorption processes in packed columns. This system absorbs ammonia or CO from a mixture with air in a watery solution that descends along the column.

The main parts of the unit are:

Packed column: it consists of a glass cylindrical column filled with Raschig rings.

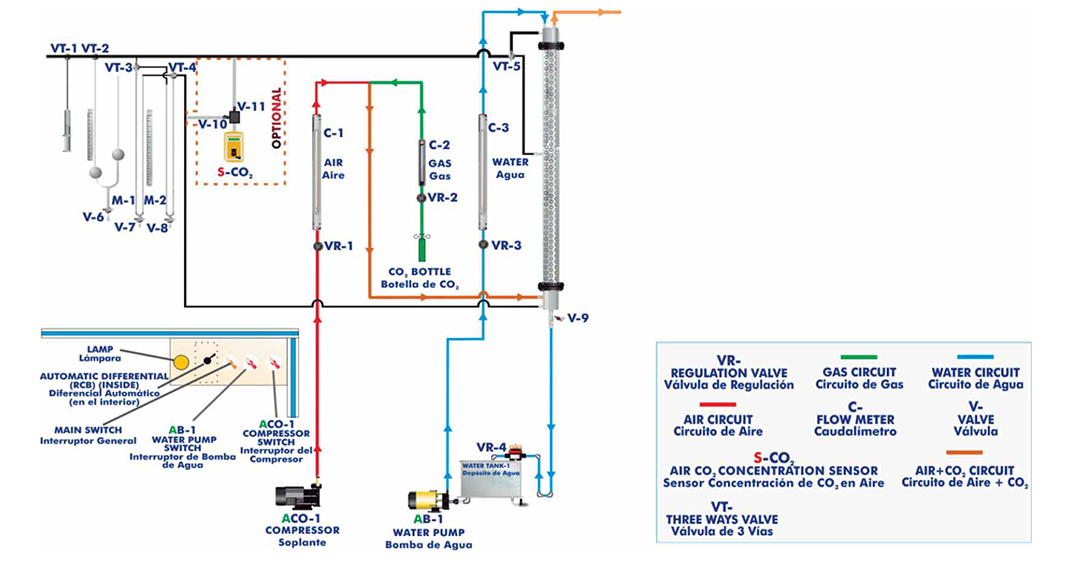

Liquid circuit (water): the liquid, that is stored in a PVC tank, is impelled towards the column by a pump. It feeds the column through its upper end using a glass diffusion shower. After crossing the column, the liquid is returned to the storage tank. The liquid flow that arrives to the column is measured with a flowmeter. Gas circuit (air and CO2): it consists of a CO2 and air (supplied by a blower) mixture current. Both gaseous currents are mixed, and later they enter the base of the column through a side inlet located below the bed level, so that the gaseous mixture is an homogeneous as possible. Both gas flows are measured by flowmeters. CO2 measuring system: it allows to determine the concentration of this gas in the currents originated from the upper and central parts of the column.

|

1.- Study of the basic principles of the absorption of a gas into a liquid using a packed column. |

8.- Investigations of the variables influencing the effectiveness of the absorption. (with the optional accessory CAG/M). |

This unit is mounted on an anodized aluminum rigid structure, with panels of painted steel.

This unit has wheels for its mobility.

Main metallic elements of stainless steel.

Diagram in the front panel with similar distribution to the elements in the real unit.

| Packed column: |

It consists of a glass cylindrical column of 1400 mm of height and 75 mm of internal diameter. |

| Liquid circuit (water): |

A PVC glass storage tank (40 l. capacity). |

| Gas circuit (air and CO2): |

Compressor (blower) provides a maximum flow of 6 m3 /h and a maximum pressure of 1bar. |

| Instrumentation for the analytical measurement of CO2: |

A glass syringe of 100 ml capacity, dedicated to extract the specific quantities of a sample to be analysed. |

| There are transparent elements allowing a better visualization of the process. | |

| Electrical console, with: | Lamp. Automatic differential (RCB). Compressor switch. Pump switch. |

| Cables and accessories, for normal operation. | |

| Manuals: |

This unit is supplied with the following manuals: Required Services, Assembly and Installation, Starting-up, Safety, Maintenance & Practices Manuals. |

|

- Electrical supply: single-phase, 220V. / 50Hz. or 110V. / 60 Hz. |

| Dimensions |

1000 approx. x 740 x 2600 mm. (39.37 x 29.13 x 102.3 inches approx. |

| Weight |

100 Kg. approx.(220 pounds approx.). |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.