Khả năng thực hành

1. Nghiên cứu các quá trình khác nhau, với thiết bị đầy đủ của chúng, sử dụng hệ thống gia nhiệt và làm mát.

2. Nghiên cứu nhũ tương

3. Thanh trùng sữa bột theo lô.

4. Chế biến các sản phẩm sữa lên men.

5.- Sản xuất sữa chua

6. Chuẩn bị và bảo quản hỗn hợp kem.

7. Chuẩn bị nhũ tương bơ thực vật và bơ thực vật.

8.- Đo nhiệt độ truyền.

9.- Tính toán chuyển nhiệt.

10. Nghiên cứu hệ thống sưởi ấm, làm mát và làm mát.

Các thực tiễn khác:

Cảm biến.

12-30.- Thực tiễn với PLC

|

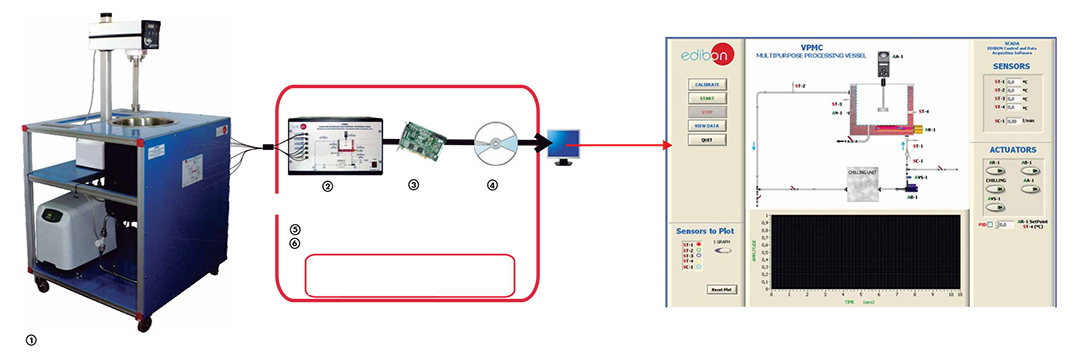

1. VPMC. Unit: The VPMC unit is a type batch equipment, suitable to demonstrate the different mixing processes in the alimentary industry.As it is a multiprocess vessel, several mixing tasks will be able to be carried out. Furthermore, it has a temperature control necessary to make easier the mixing tasks which require it, such as the help to carry out the complex emulsion tasks. The VPMC unit has all the necessary to: mix, emulsify, heat, pasteurise, incubate, cool, chill, cure. As well as the preparation of food products forfurther processing, it allows to produce finished products in batch sizes from 5 up to 30 l. maximum. Anodized aluminum structure and panels of painted steel. Diagram in the front panel. Stainless steel jacketed process vessel, capacity: 30 l. Batch sizes: from 5 up to 30 l. (depending on the mixture being processed). Max. vessel contents temperature: 85º C. Heating element, computer controlled. Emulsifier/Mixer unit of high speed with DC motor, this emulsifier is computer controlled. 4 Different emulsifier heads are supplied. Chilled water circulation system: chilling unit with compressor motor and water recirculating centrifugal pump, computer controlled. PID control of the temperature of the product into the process vessel. 4 Sensors to measure: products temperature in the vessel, temperatures for controlling the water temperature. Flow rate of cold or chilled water is controlled. Level switch in the process vessel to protect the heating element. |

|

2. VPMC/CIB.Control Interface Box: With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the PC of all parameters involved in the process. Calibration of all sensors involved in the process. Realtime curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to |

|

3. DAB. Data Acquisition Board: PCI Express Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs. Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs. |

|

4. VPMC/CCSOF. PID Computer Control+Data Acquisition+Data Management Software: Flexible, open and multicontrol software. Management, processing, comparison and storage of data. Sampling velocity up to 250 KS/s (kilo samples per second). It allows the registration of the alarms state and the graphic representation in real time. |

|

5. Manuals: This unit is supplied with 8 manuals |

|

6. Cables and Accessories: for normal operation Dimensions (approx.) =Unit: 8 x 800 x 1250 mm. Weight: 150 Kg. 00 Control Interface Box: 490 x 330 x 310 mm. Weight: 10 Kg. |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.