With the unique X-ray Guide Tube the bench top XGT-5200 systems allow convenient access to X-ray fluorescence analysis with high spatial resolution – from 1.2 mm down to 10 µm. There is no sample preparation or vacuum required – the object is simply placed in the sample chamber and analysed at normal atmospheric pressure. Fully integrated software controls sample movement, acquisition options and data analysis (including qualitative and quantitative analysis, and composite image generation). From when a sample is put in the chamber, just a few seconds are needed until an acquisition is started, aided by intuitive “point and click” selection of the analysis position.

The sample is visualised with coaxial geometry, so that parallax errors are removed. You have absolute confidence that where you see is where you sample.

Two X-ray guide tubes are provided in the instrument, allowing the user to simply switch between a micro and macro beams, so that a range of experiments can be accommodated. The high intensity beam delivered by these guide tubes ensures that acquisition times are kept to a minimum. The mono-capillary design of these guide tubes are ideally suited for high intensity element imaging, even of samples which are not perfectly flat.

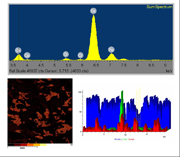

XRF mapped images are easily obtained through automated sample scanning, and the provision of a second detector beneath the sample enables simultaneous acquisition of X-ray transmission images. The additional structural information provided by this technology is extremely useful for locating regions of interest, or interrogating a sample's internal structure.

The unique x-ray guide tube technology of HORIBA provides the highest spatial resolution micro-XRF analysis, with x-ray beam diameters down to 10 µm. The high intensity, ultra-narrow beams provided by the guide tubes allow fast, non-destructive analysis of microscopic features.

In combination with XRF imaging, the XGT-7200 allows transmitted X-ray images to be acquired. This can be used to perform internal structural analyses and identify regions of interest not visible to the eye. Scanning is done with a narrow perpendicular beam, resulting in clear penetrating images even for non-flat samples such as cylindrical parts.

The XGT-7200 system offers the user unique Dual Vacuum Modes for sample analysis – switching between the two modes takes just a few seconds. In Full Vacuum Mode the entire sample chamber is subjected to vacuum conditions to ensure the ultimate sensitivity to light elements. In Partial Vacuum Mode the sample is maintained at atmospheric pressure whilst a vacuum is drawn around the detector and capillary optics. This mode is ideally suited for analysis of water containing samples such as biological tissue, and fragile archaeological/museum objects.

The accommodating sample chamber enables a wide range of samples to be analyzed, from a 10 µm spot analysis on a microscopic feature, to mapped analysis of areas as large as 10cm x 10cm.

Intuitive software allows easy control of instrument hardware, fast sample visualization and selection of measurement region, and full data analysis. Functions include automated peak identification, quantitative measurements, RGB composite image generation, line profile analysis.

| XGT System |

High Sensitivity Model (Spatial Resolution: 10 µm, 100 µm) Standard Type (Spatial Resolution: 100 µm) |

| Transmitted X-ray Detector | TYPE Ⅰ: O* (Option) TYPE Ⅱ: O *The transmitted X-ray image window is displayed during mapping even if the X-ray detector is not installed. |

| Optical Image |

Full Sample Optical Image Observation System TYPE Ⅱ: O (X2-X16) Enlarged Optical Image Coaxial Observation System

Measurement Position Setting from the Optical Image |

| Specifications for All XGT-5200 Models |

X-ray Tube: 50 kV max, 1 mA, Rh target Software |

| Peripherals | Vacuum Pump · Color Printer · MO Drive (Option) · CD-RW Drive (Option) ·17-in LCD Monitor (Option)· Transmitted Light Illumination System(Option) |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.