PID CONTROL

PID CONTROL1.- Study of a gas turbine operation.

2.- Determination of the gas turbine efficiency.

3.- Determination of the compressor operation point.

4.- Study of a gas turbine operation as a jet engine.

5.- Operation with power turbine.

6.- Determination of fuel consumption.

7.- Thermal efficiency.

8.- Air standard cycle.

9.- Heat balance.

10.-Work ratio.

11.-Pressure ratio.

12.-Pressure loss.

13.-Air and fuel ratio.

14.-Combustion efficiency.

15.-Recording the turbine characteristic curve.

16.-Determination of the efficiency of the compressor.

17.-Determination of the efficiency of high pressure turbine.

18.-Determination of the efficiency of output turbine (low pressure).

19.-Temperatures measurements.

20.-Effective turbine output power.

21.-Safety systems in the operation of a gas turbine.

22.-Thrust measurement.

Other possible practices:

23.-Sensors calibration.

24-42.- Practices with PLC.

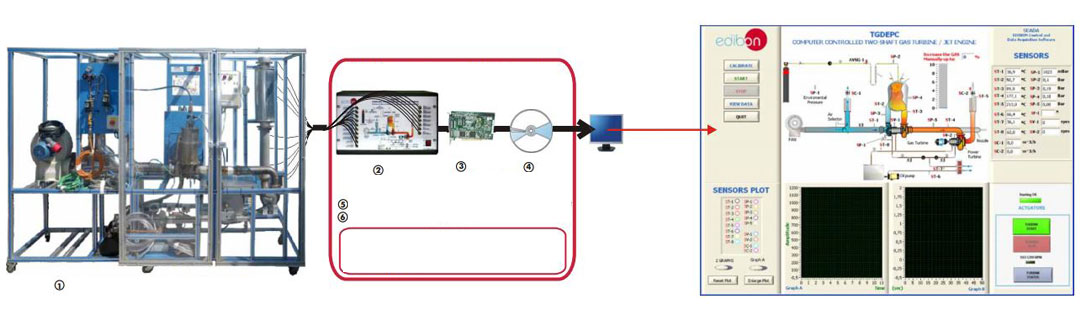

1. TGDEPC. Unit

The TGDEPC turbine is a teaching unit for the operation demonstration of a Double Shaft Gas Turbine for electric generation and for other uses too. Moreover, the unit can be configurated as a Jet Engine.

High Pressure Turbine, that it is the Gas Generative Turbine: speed range: 60,000-120,000 rpm; max. compression ratio:

2:1; mMax. fuel consumption: 20 kg/hour.

Low Pressure Turbine (Power Turbine): speed range (r. p. m.): 15,000-25,000 rpm; electrical power: measurement range: 0- 1,500W.

Asynchronous (motor) generator, computer controlled; speed range: 1,500-3,000 rpm.

Operation as a jet engine: turbine speed range: 60,000-160,000 rpm; trust nozzle, with force sensor; trust measuring range: 0-50 N.

Start fan for starting the turbine and gas sweep. Line of fuel gas. Ignition electrode, computer controlled. Ionization electrode, computer controlled. Lubrication installation (oil tank, gear pump, filtration unit, etc). Plate heat exchanger for cooling the oil of the turbines. Exhaust gas outlet and exhaust mufler.

Sensors and instrumentation: 8 temperature sensors, 2 speed sensors, 5 pressure sensors, 2 flow sensors, 1 force sensor, 4 manometers, 3 high pressure switches, ATEX flowmeter for measuring the gas consumption, current and voltage measurement, handling box with PLC and safety system to prevent faults.

Operation with propane.

2. TGDEPC/CIB. Control Interface Box:

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process. Calibration of all sensors involved in the process. Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time control with flexibility of modifications from the computer keyboard of the parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board:

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs. Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/Outputs.

4. TGDEPC/CCSOF. Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data. Sampling velocity up to 250,000 data per second. It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation.

6. Manuals: This unit is supplied with 8 manuals.

Dimensions (approx.)= Unit: 2500 x 700 x 1800 mm. Weight: 250 Kg.

Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.