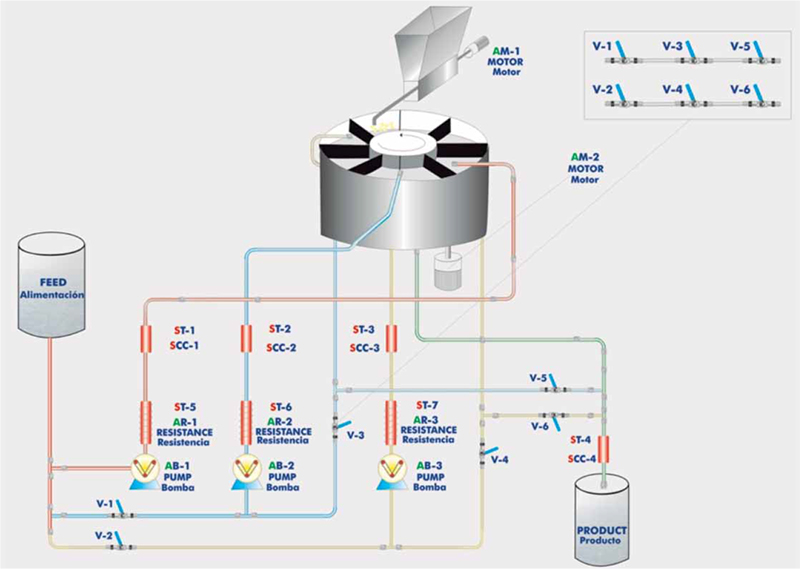

The “UESLB” unit is laboratory-scale unit designed for studying the separation of a soluble fraction from a solid with the helpof a solvent in a continuous multistage and countercurrent way.

The unit utilises a continuous feed, counter current flow, multiple stage (but may also configured as one or two stage process for teaching purposes), rotary extractor system of the type frequently seen in industrial applications. The effects of temperature, multiplestages, and throughput rate can all be investigated.

The design of the unit is based on the continuous rotation extraction cell used in industrial scale, which is called ‘Rotocel’.This is the main part of the solid/liquid extraction system and it is divided into compartments. The raw material is fed into these compartments from the input hopper. The material is then passed under three solvent sprinklers, and the dissolved product captured in three drainage compartments. Pumps are provided to pump the product from the drainage compartment of one stage to the sprinkler of the next stage. At the end of the process the spent carrier material

will go to a collection container. The solid carrier can be a light porous material. It can be impregnated with a salt such as sodium bicarbonate or potassium bicarbonate , which is then extracted by the process.

|

1.- Demonstration of the operation of a continuous multiple stage process. |

9.- Mass balances. |

|

-Electrical supply: single-phase, 220V./50Hz or 110V./60Hz. |

| Unit |

- Dimensions: 705 x 570 x 1680 mm. approx. (27.75 x 22.44 x 66.14 inches approx.) - Weight: 120 Kg. approx. (264.5 pounds approx.) |

| Electronic console |

- Dimensions: 490 x 330 x 310 mm. approx. (19.29 x 12.99 x 12.20 inches approx.) - Weight: 10 Kg. approx. (22 pounds approx.) |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.