| Park Systems’ advanced Crosstalk Elimination (XE) scan system effectively addresses all of the above-mentioned problems. In this configuration, we used a 2-dimentional flexure stage to scan the sample in only the XY direction, and a stacked piezoelectric actuator to scan the probe cantilever in the Z direction only. The flexure stage used for the XY scanner is made of solid aluminum. It demonstrates high orthogonality and an excellent out-of-plane motion profile. The flexure stage can scan large samples (~1 kg) up to a few 100 Hz in the XY direction. This scan speed is sufficient because the bandwidth requirement for the XY axes is much lower than that for the Z axis. The stacked piezoelectric actuator for the Z-scanner has a high resonance frequency (~10 kHz) with a high pushpull force when appropriately pre-loaded. |

| XE scan system | XY flexure scanner |

|

Independent, loop XY and Z flexure scanners for sample and probe tip |

|

Flat and orthogonal XY scan with low residual bow |

XE-Peformence

| Figure 9. Zero background curvature by Park Systems XE-system (a) and typical background curvature of a conventional AFM system with a tube scanner (b). (c) shows the cross section of these background curvatures. |

| Figure 9. shows unprocessed AFM images of a bare silicon wafer taken with the XE-system (a), and with a conventional AFM (b). Since the silicon wafer is atomically flat, most of the curvatures in the image are scanner-induced artifacts. Figure 9. (c) shows the cross section of the images in Figure 9. (a) and (b). Since the tube scanner has intrinsic background curvatures, the maximum out-of-plane motion is as much as 80 nm when the X-axis moves 15 μm. The XE scan system has less than 1nm of out-of-plane motion for the same scan range. Another advantage of the XE scan system is its Z-servo response. Figure 10. is an image of a porous polymer sphere (Styrene Divinyl Benzene), whose diameter is about 5 µm, taken with the XE-system in Non-Contact mode. Since the Z-servo response of the XE-system is very accurate, the probe can precisely follow the steep curvature of the polymer sphere as well as small porous surface structures without crashing or sticking to the surface. Figure 11. shows another example that demonstrates the high performance of the z-servo response with a flat background. |

|

|

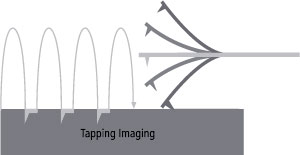

| In True Non-Contact™ Mode, the tip-sample distance is successfully maintained at a few nanometers in the net attractive regime of inter-atomic force. The small amplitude of tip oscillation minimizes the tip-sample interaction, resulting in superb tip preservation and negligible sample modification |

| True Non-Contact™ Mode | Tapping Imaging |

|

|

| - Less tip wear = Prolonged high-resolution scan - Non-destructive tip-sample interaction = Minimized sample modification - Immunity from parameter dependent results |

- Quick tip wear = Blurred low-resolution scan - Destructive tip-sample interaction = Sample damage and modification - Highly parameter-dependent |

| The sharp end of an AFM tip is so brittle that once it touches a sample, it becomes instantly blunt and limits the resolution of an AFM and reduces the quality of the image. For softer samples, the tip will damage the sample and also result in inaccuracies of sample height measurements. Consequently, preserving tip integrity enables consistent high resolution and accurate data. True Non-Contact Mode of theXE-AFM superbly preserves the tip, resulting in much longer tip life and less sample damageThe figure, displayed in 1:1 aspect ratio, shows the unprocessed raw data image of a shallow trench isolation sample imaged by the XE-AFM, whose depth is also confirmed by scanning electron microscope (SEM). The same tip used in the imaging of the sample shows no tip wear even after taking 20 images. |

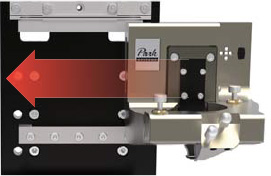

| 2D Flexure-Guided Scanner with 10 µm x 10 µm Scan Range | Manual XY Sample Stage |

|

The measurement location of the sample is easily and precisely controlled by the manual XY stage. The travel range of the XY sample stage is 13 mm x 13 mm. |

| The XY scanner consists of symmetrical 2-dimensional flexure and high-force piezoelectric stacks provides high orthogonal movement with minimal out-of-plane motion as well as high responsiveness essential for precise sample scanning in the nanometer scale. The compact and rigid structure was designed for low noise, high speed servo response. |

| Slide-to-Connect SLD Head | Park XE Control Electronics with DSP Board in Controller |

|

|

|

The AFM head is easily inserted or removed by sliding it along a dovetail rail. The low coherency of the Super Luminescence Diode (SLD) enables accurate imaging of highly reflective surfaces and precise measurements for pico-Newton Force-distance spectroscopy. The SLD wavelength eliminates interference issues for users interested in combining the AFM with experiments in the visible spectrum. |

The nanoscale signals from the AFM are controlled and processed by the high performance Park XE electronics. With its low noise design and high speed processing unit, Park XE electronics successfully realize True Non-Contact™ mode ideal for nanoscale imaging as well as precise voltage and current measurement.

• High performance processing unit of 600 MHz and 4800 MIPS speed |

| Accessible Sample Holder | Manual Optics Stage |

| The unique head design can handle up to 100 mm sample size and allows for easy side access to the sample and tip. | The focus mechanism for the on-axis optics is adjusted manually. |

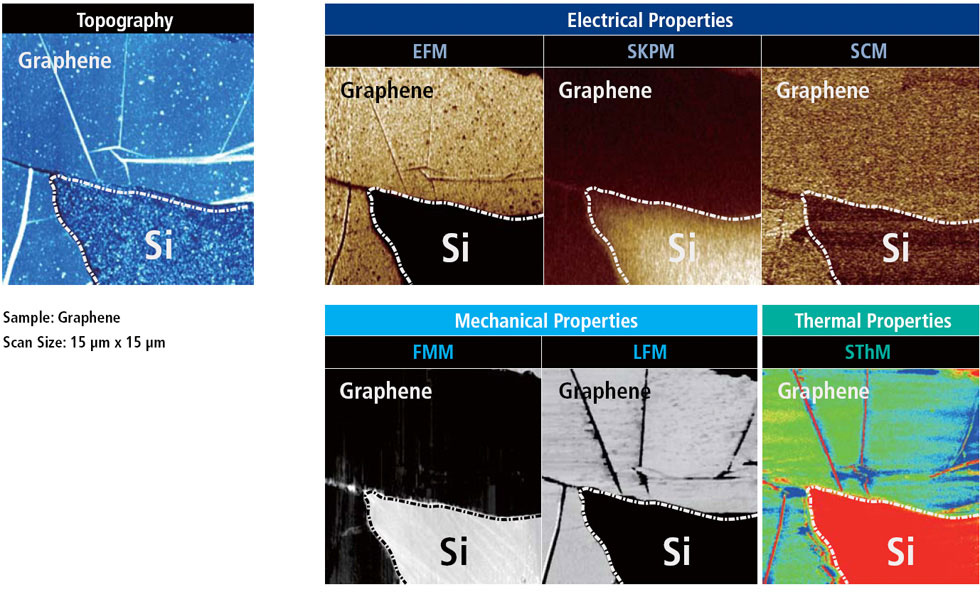

Supports Park’s most extensive range of SPM modes and options in the industry |

| Today's researchers need to characterize a wide range of physical properties under diverse measurement conditions and sample environments. Park Systems provides the most extensive range of SPM modes, the largest number of AFM options, and the best option compatibility and upgradeability in the industry for advanced sample characterization. |

XY Scanner |

Single-module flexure XY scanner with closed-loop control Scan range: 100μm x 100μm 50μm x 50μm 10μm x 10μm |

Manual Stage |

XY travel range: 13 × 13 mm Z travel range: 29.5 mm Focus travel range: 70 mm |

Z Scanner range |

Guided high-force Z scanner Scan range: 12 µm 15 µm |

Sample Mount |

Sample size: Up to 100 mm Thickness: Up to 20 mm |

Vision |

Direct on-axis vision of sample surface and cantilever Coupled with 10× objective lens (20× optional) Field-of-view: 480 × 360 µm CCD: 1 Mpixel |

Software |

XEPDedicated system control and data acquisition software XEIAFM data analysis software |

Electronics |

High performance DSP: 600 MHz with 4800 MIPS Maximum 16 data images Maximum data size: 4096 × 4096 pixels Signal inputs: 20 channels of 16 bit ADC at 500 kHz samplings Signal outputs: 21 channels of 16 bit DAC at 500 kHz settling Synchronous signal: End-of-image, end-of-line, and end-of-pixel TTL signals Active Q control (optional) Cantilever spring constant calibration (optional) CE Compliant Power: 120 W Signal Access Module (Optional) |

AFM Modes (*Optionally available): |

|

Standard Imaging |

True Non-Contact AFM Basic Contact AFM Lateral Force Microscopy (LFM) Phase Imaging Intermittent (tapping) AFM |

Dielectric/Piezoelectric Properties* |

Electric Force Microscopy (EFM) Dynamic Contact EFM (DC-EFM) Piezoelectric Force Microscopy (PFM) PFM with High Voltage |

Magnetic Properties* |

Magnetic Force Microscopy (MFM) Tunable MFM |

Electrical Properties* |

Conductive AFM I-V Spectroscopy Scanning Kelvin Probe Microscopy (SKPM/KPM) SKPM with High Voltage Scanning Capacitance Microscopy (SCM) Scanning Spreading-Resistance Microscopy (SSRM) Scanning Tunneling Microscopy (STM) Time-Resolved Photo Current Mapping (Tr-PCM) |

Chemical Properties* |

Chemical Force Microscopy with Functionalized Tip Electrochemical Microscopy (EC-STM and EC-AFM) |

Force Measurement* |

Force Distance (F-D) Spectroscopy Force Volume Imaging |

Mechanical Properties* |

Force Modulation Microscopy (FMM) Nanoindentation Nanolithography Nanolithography with High Voltage Nanomanipulation Piezoelectric Force Microscopy (PFM) |

Optical Properties* |

Tip-Enhanced Raman Spectroscopy (TERS) Time-Resolved Photo Current Mapping (Tr-PCM) |

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.