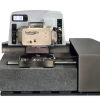

Kính hiển vi lực nguyên tử Dimension HPI

Liên hệ

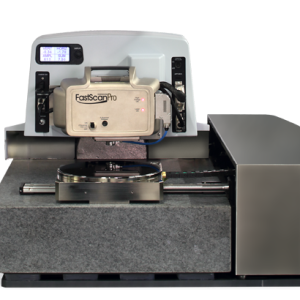

Dimension HPI

Designed specifically for high-volume, production environments, the Dimension HPI system enables automated measurements of many AFM modes while ensuring the utmost ease of use and the lowest cost per measurement for quality control, quality assurance, and failure analysis. Using contact, tapping, and PeakForce Tapping mode techniques, Dimension HPI enables users to precisely control probe-to-sample interaction, providing long tip life-times with high-accuracy results in thousands of measurements.

Widest Range of Measurements

From exclusive PeakForce Tapping modes to traditional AFM modes, Dimension HPI provides the greatest range and flexibility to meet specific manufacturing metrology needs on a wide range of samples, without the complexity usually associated with AFM research setups.

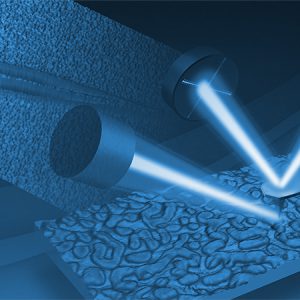

Fast Nanoelectrical Metrology

FastScan technology with Conductive-AFM (CAFM) can perform nanoscale current measurements at high scan rates, significantly increasing the efficiency of failure analysis measurements. Using a small magnetic force microscopy (MFM) cantilever, FastScan HPI provides greater than 10x scan rate improvements for MFM applications with exceptional data quality using PeakForce Tapping. PeakForce KPFM™ provides the highest spatial resolution and most accurate measurements of surface potential. PeakForce TUNA™ provides the most sensitive conductivity measurements.

Precise Nanomechanical Mapping

Bruker’s unique PeakForce QNM and FASTForce Volume™ nanoscale mechanical mapping modes can precisely map mechanical properties—modulus, stiffness, adhesion, dissipation, and deformation— while simultaneously imaging sample topography and electrical properties. PeakForce QNM enables non-destructive measurements on polymers, thin films, and nanoscale defects not measurable by transmission electron or scanning electron microcopy techniques.