Hysitron PI 80 SEM Picolndenter

Liên hệ

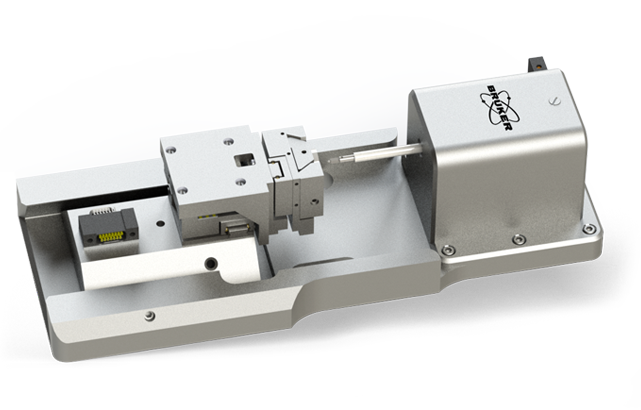

Hysitron PI 80 SEM PicoIndenter

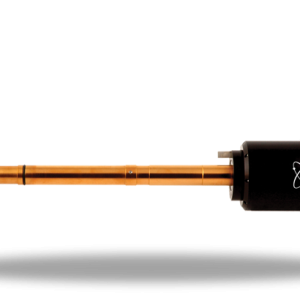

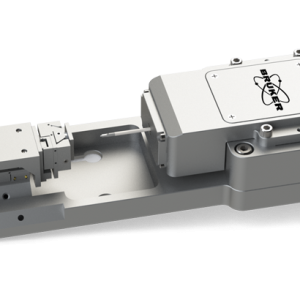

Bruker’s PI 80 SEM PicoIndenter is a depth-sensing nanomechanical test instrument specifically designed to augment the imaging capabilities of scanning electron microscopes (SEM, FIB/SEM, PFIB). With this base nanoindentation tool, it is possible to perform quantitative in-situ nanomechanical testing while simultaneously imaging with the SEM. Featuring Bruker’s industry-leading capacitive transducer, PI 80 provides exceptional performance and superior stability at the nanoscale. Its compact, low-profile design makes the instrument ideally suited for small-chamber SEMs, as well as standalone Raman and optical microscopes, beamlines, and more. With its combination of features, testing modes, and optional accessories, the PI 80 SEM PicoIndenter offers an excellent introduction to advanced nanomechanical property testing inside your SEM.

In-Situ Mechanical Data Synchronized with SEM Imaging

In-situ mechanical data acquired with the Hysitron PI 80 is synchronized with SEM imaging and displayed in side-by-side video format. Simultaneous mechanical measurements and SEM data enables a more complete understanding of material deformation behavior. In the example at left, discontinuities in the load-displacement data are correlated to the onset of fracture observed in a FIB-milled beam containing copper interconnects and brittle dielectric material.

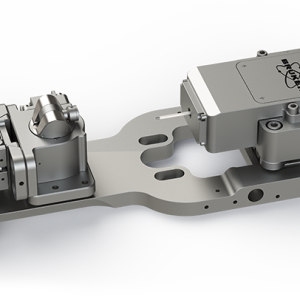

Designed to Augment Your SEM

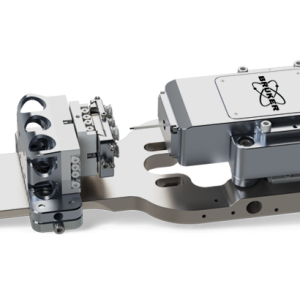

With the compact form of Bruker’s capacitive transducer, Hysitron PI 80 can be mounted directly onto the SEM stage without being a permanent fixture in the microscope. The sample positioning stages accommodate samples up to 20 mm thick while providing precise sample positioning across more than 3 mm in all three directions (XYZ). In addition, the mechanical coupling of the sample stage and the transducer provides a stable, rigid platform for nanomechanical testing. Overall, this in-situ instrument enables stage tilt and working distance optimized for complementary SEM imaging and standard nanomechanical testing.