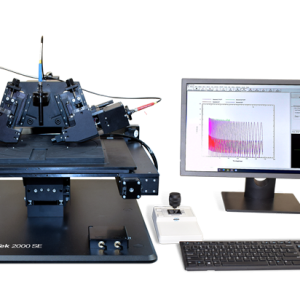

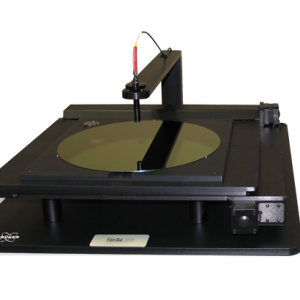

FilmTek 2000 PAR-SE

Liên hệ

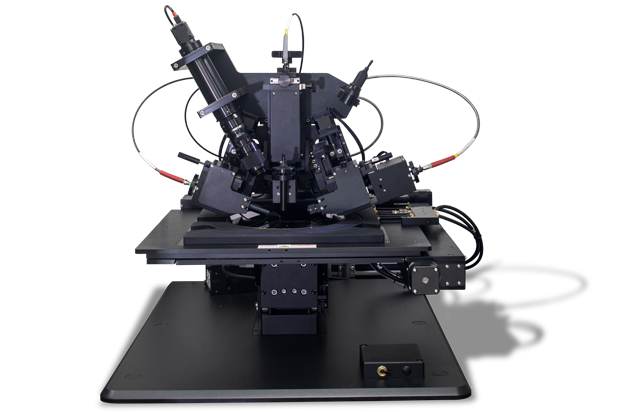

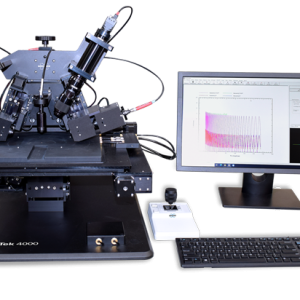

FilmTek 2000 PAR-SE

Combining patented Multi-Angle Differential Polarimetry (MADP) and Differential Power Spectral Density (DPSD) technology, the FilmTek™ 2000 PAR-SE utilizes multi-angle and multi-modal data collection to independently measure film thickness and index of refraction. By independently measuring index and thickness, the FilmTek 2000 PAR-SE is far more sensitive to changes in films, particularly films within multi-layer stacks, than existing metrology tools that rely on conventional ellipsometry or reflectometry techniques. The FilmTek 2000 PAR-SE is a fully-integrated package, paired with advanced material modeling software to make even the most rigorous measurement of patterned wafers reliable and intuitive.

Measurement Capabilities

Enables simultaneous determination of:

- Multiple layer thicknesses

- Indices of refraction [ n(λ) ]

- Extinction (absorption) coefficients [ k(λ) ]

- Energy band gap [ Eg ]

- Composition (e.g., %Ge in SiGex, % Ga in GaxIn1-xAs, %Al in AlxGa1-xAs, etc.)

- Surface roughness

- Constituent, void fraction

- Crystallinity/Amorphization (e.g., of Poly-Si or GeSbTe films)

- Film gradient

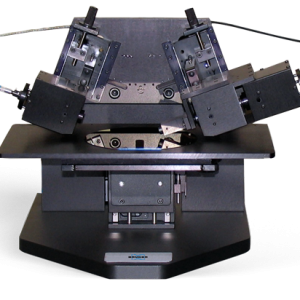

System Components

Standard:

- Spectroscopic ellipsometry with rotating compensator design (295 nm – 1700 nm)

- Multi-angle, polarized spectroscopic reflection (190 nm – 1700 nm)

- Measures film thickness and index of refraction independently

- Multi-Angle Differential Polarimetry (MADP) technology with SCI’s patented Differential Power Spectral Density (DPSD) technology

- Ideal for measuring ultra-thin films (0.03 Å repeatability on native oxide)

- Camera for imaging measurement location

- Pattern recognition

- 50 micron spot size

- Advanced material modeling software

- Bruker’s generalized material model with advanced global optimization algorithms

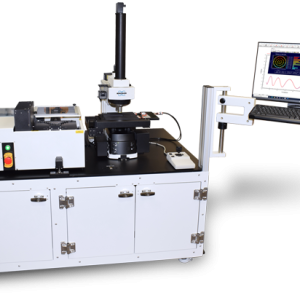

Optional:

- Generalized ellipsometry (4×4 matrix generalization method) for anisotropy measurements (nx, ny, nz)

- Cassette to cassette wafer handling

- FOUP and SMIF compatible

- Pattern recognition (Cognex)

- SECS/GEM