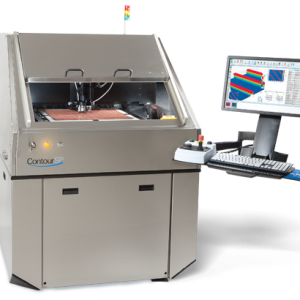

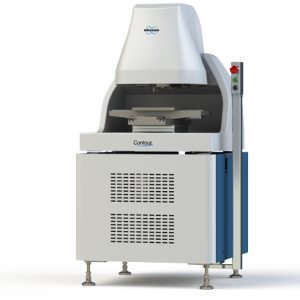

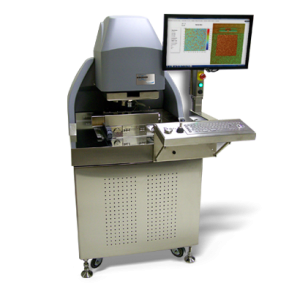

The ContourX-200 Optical Profilometer provides the perfect blend of advanced characterization, customizable options, and ease of use for best-in-class fast, accurate, and repeatable non-contact 3D surface metrology. The gage-capable, small footprint system offers uncompromised 2D/3D high-resolution measurement capabilities using a larger FOV 5 MP digital camera and new motorized XY stage. Boasting unmatched Z-axis resolution and accuracy, the ContourX-200 provides all the industry recognized advantages of Bruker’s proprietary white light interferometry (WLI) technology without the limitations of conventional confocal microscopes and competing standard optical profilers.

Uncompromised, Best-in-Class Metrology

Built upon over four decades of proprietary WLI innovation, the ContourX-200 optical profilometer exhibits the low noise, high-speed, accuracy, and precision results that quantitative metrology requires. With the use of multiple objectives and integrated feature recognition, features can be tracked over a variety of fields of view and at sub-nanometer vertical resolution, providing scale-independent results for quality control and process monitoring applications in very diverse industries. ContourX-200 is robust in all surface situations from 0.05% to 100% reflectivity. New hardware features include an innovative stage design for larger stitching capabilities and a 5MP camera with a 1200×1000 measurement array for lower noise, larger field-of-view, and higher lateral resolution.

Widest Application Analysis Capabilities

Utilizing powerful VisionXpress and Vision64 user interfaces, the ContourX-200 offers thousands of customized analyses for productivity in labs and on the factory floors. Bruker’s new Universal Scanning Interferometry (USI) measurement mode provides fully automated, self-sensing surface texture, optimized signal processing while delivering the most accurate and realistic computation of the surface topography being analyzed. The larger FOV provided by the system’s new camera and flexibility afforded by the new motorized XY stage enables more flexibility and higher throughput for a broad range of samples and parts. The hardware and software combine to provide streamlined access to top optical performance, completely outclassing comparable metrology capabilities.