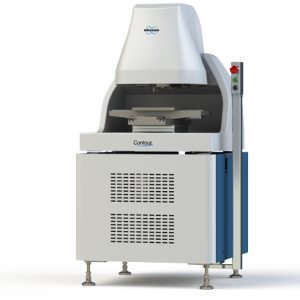

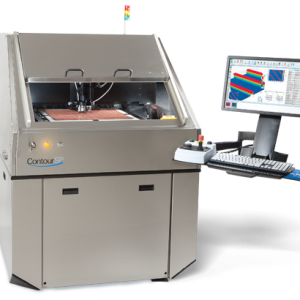

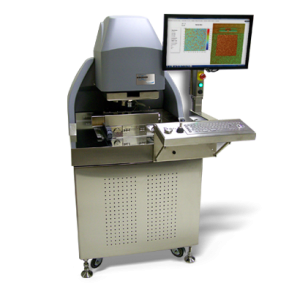

NPFLEX-1000

The NPFLEX-1000 floor-standing white light interferometer (WLI) offers the most accurate and flexible solution for evaluating nano- to macro-features on large parts in precision machining QA/QC. Key features include a large form-factor open-gantry, robust bridge architecture, and swivel head design with 300 mm of distance between stage and objectives. This exclusive design allows NPFLEX-1000 to accomodate the widest variety of sample sizes and shapes and access the most challenging orientations.

With this unique design, combined with the ease-of-use advantages of our next-generation optical profiler technology, NPFLEX-1000 delivers gage-capable surface texture and roughness measurements with the throughput and repeatability operators need in dynamic sectors such as automotive, medical, and large-scale additive manufacturing.

Optimized for Productivity Both in the Lab and on the Factory Floor

The NPFLEX-1000 delivers the most accurate and repeatable surface texture and roughness metrology for almost any precision manufacturing application.

The NPFLEX-1000 delivers a unique range of critical advantages:

- Ultimate large-part and high-slope surface compatibility reduces sample preparation and increases the range of measurement surfaces accessible per part;

- Exceptional ease-of-use empowers operators at any experience level to obtain expert results;

- Super-fast automated measurement and analysis routines provide decreased time-to-result; and

- Highly robust bridge architecture and integrated vibration isolation offer long-term accuracy and reliability for production environments.

Extreme Part Size and Shape Freedom

The NPFLEX-1000 delivers ultimate sample-size freedom and the unique ability to measure high-slope surfaces and difficult orientations on large parts thanks to Bruker’s most innovative and exclusive technology, including:

- Large gantry and swivel head design: Provide unique access to difficult orientations on large parts;

- Long focal-length objectives: Expands the possibilities for sample types;

- Bore-Scope Objective: Captures 3D data as far as 150 mm down the inner walls of cylinders or bores; and

- Fold-Mirror: Offers non-destructive analysis of inside diameters of bores and cylinders and along sidewalls of bowl shapes with high slopes up to 70°.

Customizable, Application-Specific Configurations

The NPFLEX-1000 system offers many options to customize its operation for specific applications.

Key features include:

- Open-access robust bridge architecture;

- Material-insensitive measurement;

- Allows custom fixtures and mounts (e.g., a vacuum wafer chuck or universal sample mounting kit); and

- For specialized applications, customized routines can be created specifically for your requirements.

Additional accessories further adapt the system to fit unique samples and applications. Contact us for more information.

▲ CNC-milled part (p.7)

Built for Speed

The NPFLEX-1000 offers extreme usability at uncompromising speeds, enabling critical improvements in throughput for production environments.

Key features include:

- Minimal sample preparation and measurement setup time;

- Fast, automated measurements and full analysis within 10 seconds;

- The most motorized stages available, allowing for easy, automated movement to any location on any part without remounting; and

- Quick and easy part switching for performing measurements on multiple surfaces.

Always Accurate and Repeatable

Whenever tight control of environmental factors is not possible, the NPFLEX-1000 still maintains excellent reproducibility thanks to its integrated vibration isolation and self-calibration. A built-in reference signal laser interferometer continuously calibrates the temperature to account for environmental influences and to always ensure high accuracy and reproducible measurements, ideal for applications that require absolute long-term stability.