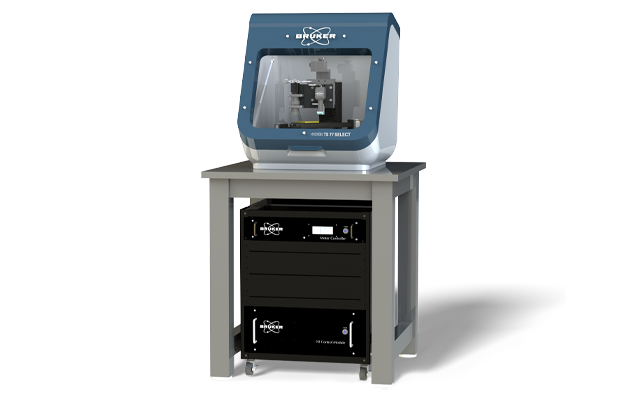

Hệ thống thử nghiệm cơ học Hysitron TS 77 Select Nanoindenter

Liên hệ

Hysitron TS 77 Select Nanoindenter

The Hysitron TS 77 Select automated benchtop nanomechanical and nanotribological test system provides the highest level of performance, functionality, and accessibility of any instrument in its class. Built around Bruker’s renowned TriboScope capacitive transducer technology, this new test system delivers reliable mechanical and tribological characterization over nanometer-to-micrometer length scales. Supporting the most prominent testing modes, the TS Select is an affordable entry into quantitative nanoindentation, dynamic nanoindentation, nanoscratch, nanowear, and high-resolution mechanical property mapping.

TS 77 Select Design

- Color optics

- Sample chuck

- Anti-vibration

- Environmental enclosure

- Piezo scanner

- Capacitive transducer

- Sample translation staging

- Granite frame

TS 77 Select Testing Modes: Your Essential Toolkit

Nanoindentation – High-Precision Mechanical Characterization

Characterize the elastic modulus, hardness, creep, stress relaxation, and fracture toughness of localized microstructures, interfaces, small surface features, and thin films.

In-Situ SPM Imaging – Enabling Superior Nanomechanics

Utilizes the same probe to raster the sample surface for topography imaging as it does to conduct the nanomechanical test, ensuring superior nanomechanical characterization results, data reliability, and nanometer precision test placement accuracy.

Nanoscratch – Friction, Mar Resistance, and Thin Film Adhesion

Nanoscratch utilizes an electrostatically actuated two-dimensional transducer to apply a normal force in a controlled fashion while simultaneously measuring the force required to move the tip laterally across the sample surface. The nanoscratch option does not rely on motorized staging for lateral movement, providing the most sensitive and reliable nanoscale friction and thin film adhesion measurements in the market.

Mechanical Property Mapping – High-Speed Mapping and Fast Data Acquisition

Delivers high-speed testing capabilities, up to 180x faster than traditional nanoindentation measurements. At two nanoindentation tests per second, high-resolution mechanical property maps of inhomogeneous materials can be obtained within minutes.

Wear Testing – Quantitative Nanoscale Wear Resistance

Quantitative wear volumes and wear removal rates can be measured as a function of applied contact force, sliding speed, and number of passes. Due to the scale of testing, tribological performance of individual microstructures, interfaces, and thin films can readily be measured.

Dynamic Nanoindentation – Depth Profiling, Viscoelastic Properties

Dynamic nanoindentation superimposes a small oscillatory force over a quasi-static force component to obtain a continuous measurement of hardness and modulus as a function of depth into a material’s surface. The dynamic nanoindentation option includes a capacitive transducer optimized for dynamic measurements and controller electronics to deliver superior results as a function of testing depth, frequency, and time.