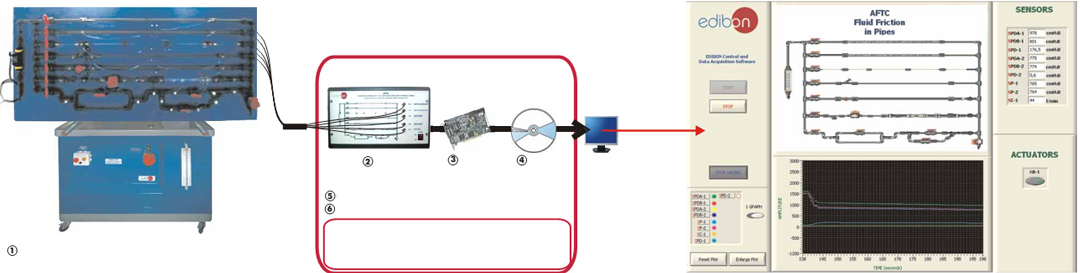

SCADA.EDIBON Computer Control System Unit: AFTC. Fluid Friction in Pipes, with Hydraulics Bench

SCADA.EDIBON Computer Control System Unit: AFTC. Fluid Friction in Pipes, with Hydraulics Bench PRACTICAL POSSIBILITIES

|

1.- Load loss by friction in a rough pipe of 17 mm of interior diameter. 32.- Load losses for a 90º elbows. |

16.- Friction coefficient in smooth and rough pipes. |

1. AFTC. Unit:

|

This unit allows the detailed study of fluid friction head losses which occur when a fluid flows through pipes, fittings and flow metering elements. |

| Anodized aluminium structure and panel in painted steel. |

| Diagram in the front panel with similar distribution to the elements in the real unit. |

| Quick connections. |

| Rapidity and facility to replace parts of the unit, in the case of failure or breaking. |

| Transparent elements. |

| Rough pipe 17 mm. dia. (PVC). Rough pipe 23 mm. dia. (PVC). |

| Smooth pipe 6.5 mm. dia. (methacrylate). Smooth pipe 16.5 mm. dia. (PVC). |

| Smooth pipe 26.5 mm. dia. (PVC). |

| Pressure sensors: 2 differential pressure sensors and 2 pressure sensors. |

| 34 pressure tappings. |

| Flow sensor. |

| Inclined seat valve. Floodgate valve. Ball valve. Flow regulation valves. |

| Inline strainer. |

| Membrane valve. |

| Abrupt broadening. Abrupt contraction |

| Venturi tube of transparent plastic. |

| Diaphragm of transparent plastic. |

|

Symmetrical bifurcation. Two 90º elbows (in S). T-junction. Inclined T-junction. 45º elbow. 90º elbow. |

| Pipes in parallel configuration. |

| Pipe section with a pitot tube and static tapping. |

|

Hydraulics Bench(FME00): |

2. AFTC/CIB. Control Interface Box:

With process diagram in the front panel. The unit control elements are permanently computer controlled. Simultaneous visualization in the computer of all parameters involved in the process. Calibration of all sensors involved in the process. Real time curves representation. All the actuators’ values can be changed at any time from the keyboard. Shield and filtered signals to avoid external interferences. Real time control with flexibility of

modifications from the computer keyboard of the parameters, at any moment during the process. Open control allowing modifications, at any moment and in real time, of parameters involved in the process. 3 safety levels: mechanical in the unit, electronic in the control interface, and the third one in the control software.

3. DAB. Data Acquisition Board

PCI Data acquisition National Instruments board to be placed in a computer slot. 16 Analog inputs. Sampling rate up to: 250 KS/s. 2 Analog outputs. 24 Digital Inputs/ Outputs.

4. AFTC/CCSOF.Computer Control+Data Acquisition+Data Management Software:

Flexible, open and multicontrol software. Management, processing, comparison and storage of data. Sampling velocity up to 250 KS/s (kilo samples per second). It allows the registration of the alarms state and the graphic representation in real time.

5. Cables and Accessories, for normal operation

6. Manuals: This unit is supplied with 8 manuals.

Control Interface: 490 x 330 x 310 mm. Weight: 10 Kg.

Dimensions (approx.) =Unit: 2100 x 850 x 2000 mm. Weight: 200 Kg

Hiện tại chưa có ý kiến đánh giá nào về sản phẩm. Hãy là người đầu tiên chia sẻ cảm nhận của bạn.